Solid-state batteries will be the “next generation revolution in the battery world”

When Hui Energy Technology announced 57mS/cm ionic conductivity, the physical limit of liquid batteries was formally penetrated – this energy revolution driven by solid-state batteries is reconfiguring the trillion-dollar industrial landscape with a triple disruptive breakthrough.

I. Solid-state battery performance breakthrough: double leap in safety and energy

1.Intrinsic safety mechanism

Non-flammable electrolyte: sulfide/oxide solid-state electrolyte completely eliminates the risk of thermal runaway, passing the 200°C hot box test (liquid batteries >80°C will be out of control)

Structural resistance: BYD blade batteries withstand the crush of 46 tons of trucks with no leakage, and the temperature of the surface of the pinch is <60°C.

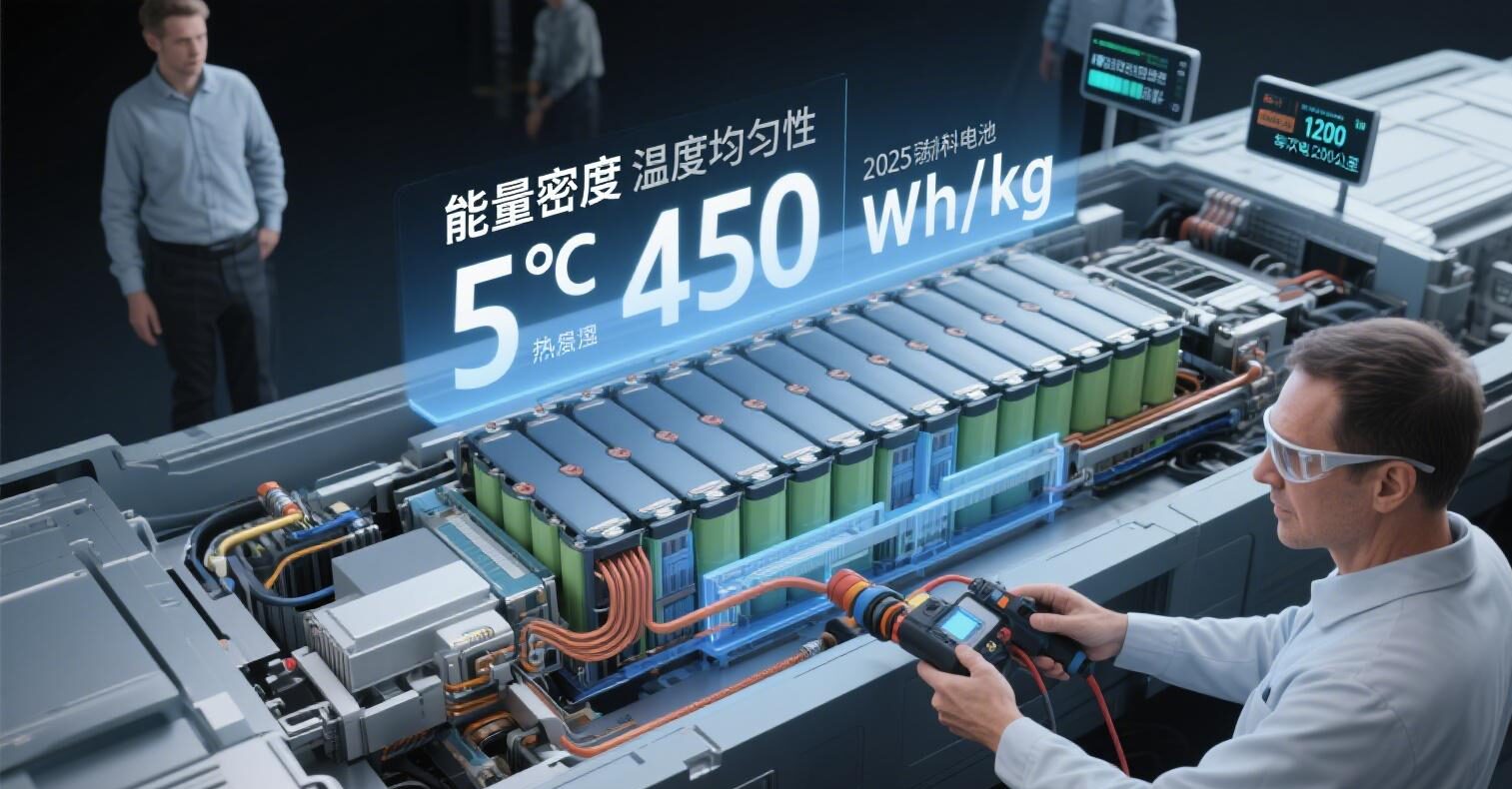

2.Energy density jump

A[Liquid Battery] –> |300Wh/kg Ceiling | B[Solid State Battery]

B –> C[Sulfide System 450Wh/kg]

B –> D[Lithium Metal Anode 720Wh/kg]

Note: Phono SF-Ceramion™ achieves room temperature conductivity of 57 mS/cm, 6 times that of liquid electrolytes1.

3. Extreme environmental adaptability

-20°C low temperature: discharge efficiency >90% (liquid battery <50%)7

6C fast charging: 4-6 minutes to 80% SOC (Mercedes-Benz Solstice™ battery empirical evidence)

II. Process Revolution: Reconfiguration and Opportunities in the Manufacturing Chain

Core equipment upgrade matrix

| process link | disruptive technology | Quantitative and Effective Enhancement | head equipment vendor |

|---|---|---|---|

| pre-filming | Dry Electrodes | Energy consumption ↓ 40%, cost ↓ 30% | Tsingyan Nako / Pioneer Intelligence |

| Nakamichi Stacker | Thermal Composite Flying Stack | 0.125 sec/chip, 99.9% yield | Beehive Energy/Li Yuan Heng |

| Interfacing | Isostatic densification | Cycle life ↑40% | Kawanishi Machine/Pilot Intelligence |

| be transformed into | High pressure activation (80MPa) | Interface impedance ↓90% | Hangke Technology |

Dry Electrode Mass Production Tipping Point

Core Parameters of the equipment to be delivered in 2025 by Qingyan Nako:

- Width: 800mm → 2026 target>1000mm

- Speed: 50m/min → negative electrode>80m/min, positive electrode>50m/min

- Compaction density: ternary positive electrode>3.5g/cm³, silicone-based negative electrode>1.6g/cm³

III. Application Upgrading: Trillion-dollar Scenario Fission

1. eVTOL (Electric Vertical Takeoff and Landing Vehicle)

- Rigid demand for energy density: >400Wh/kg (Xinjie Energy has reached 480Wh/kg)

- Safety certification breakthrough: Yihang EH216-S is equipped with solid-state batteries to realize 48-minute endurance, and will be certified for mass production by the end of 2025.

- Incremental market: China’s low-altitude economy will be 1.5 trillion in 2025, and aviation batteries will account for 20% of that amount10

2. Humanoid robot

- Continuity pain point solution: TaiLan New Energy 720Wh/kg all-solid-state battery, supporting 6 hours of continuous operation (2-3 hours for traditional batteries)

- Safety redundancy: GAC GoMate robot passes the impact test, 0 leakage risk

- Demand forecast: global demand for solid-state batteries in the field of humanoid robots will be >20GWh in 2030

3. Electric Transportation and Energy Storage

- Vehicle-grade landing:

- Fu Energy Technology sulfide all-solid-state batteries installed in 20266

- Guoxuan Gaoke “Golden Stone Battery” mass production of 400Wh/kg battery cells in 2027

- Energy Storage Economics: Tsing Tao Energy Semi-Solid State Battery Cycles >8,000 Times, Reduces LCOE by 30%

IV. Race for technology routes: the sulphide route locks in a win

Sulfide Core Advantages:

Ionic conductivity: glow energy 57mS/cm (oxide <10mS/cm)

Interface contact: self-leveling characteristics no-pressurization module, energy density ↑15%

Mass production progress:

Ningde Times 500Wh/kg lab product, 2027 vehicle loading

Toyota-Mercedes-Benz consortium to launch GWh-class production line in 2026

V. Reconstruction of industrial ecology: the rise of open technology alliance

Pfizer’s fourth-generation technology landing model:

1. Vertical division of labor:

- Pfizer provides core chemistry system (Inlay)

- Partners complete group packages and end-use applications

2. Regional manufacturing:

- Dunkirk super plant in France to go into operation in 2028 (localized supply chain in the EU)

3. Patent sharing:

- Authorizes core patents to material/device vendors to lower industry thresholds

Strategic window for equipment vendors:

companies such as Precursor Intelligence account for 28% of the value of the solid-state equipment chain through whole-line output

When the mass production cost of solid state battery drops to $150/kWh (2030), the existing liquid battery system will only have a cost advantage. Laying out the process know-how and patent ecology in advance will enable us to seize the commanding heights of the energy revolution.