Lithium Battery Technology for Robotics 2025

I.Core Performance Matrix of Lithium Battery for Robotics: Multi-dimensional Requirements Beyond Energy Density

Robot lithium batteries need to fulfill a four-dimensional performance balance:

| dimension | industrial robot | medical robot | special robot |

|---|---|---|---|

| energy density | 280-350Wh/kg | 220-250Wh/kg | 260-300Wh/kg |

| power response | 3C continuous discharge | 1.5C constant power output | 2C pulse discharge |

| security level | UN38.3 | ISO 13485 | ATEX/IECEx |

| cycle life | >4000次@80% SOH | 2000 times | 1500 times |

Typical Case:

- Tesla Optimus: 300Wh/kg ternary battery supports 4 hours of dynamic operation

- Da Vinci Surgical System: Dual battery redundancy ensures seamless switching in 0.1 seconds

- State Grid Inspection Robot: -40℃~70℃ wide temperature range operation

II.Scenario-based technology solutions

1. Industrial mobile platform: prioritizing efficiency

- Fast charging technology: Ningde Times CTP 3.0 realizes 4C super charging (80% replenishment in 15 minutes)

- Thermal management breakthroughs:

- Liquid-cooled plate thermal conductivity>5000W/mK

- Cell temperature difference control ±2℃ (±5℃ for traditional solutions)

- Co-operative power supply: parallel connection of multiple battery packs on CAN bus, supporting 12 hours of continuous operation

2. Medical and health field: safety redundancy design

- Dual-battery system: Main and backup switching time <100ms

- Biocompatible materials: Titanium alloy shell passed ISO 10993 biocompatibility certification

- Precise temperature control:

- Operating temperature 25-35℃

- Over-temperature automatic power reduction of 20% + forced cooling

3. Special applications: extreme environment adaptation

- Deep-sea operation: Oil-immersed battery packs withstand 1000m water pressure (≈100MPa)

- Explosion-proof certification: Intrinsically safe design certified to ATEX Category 1

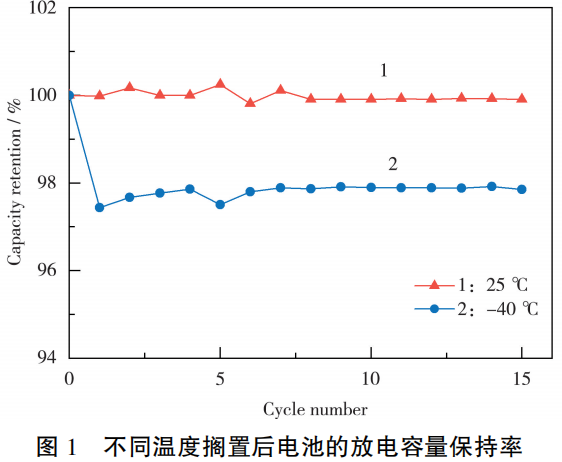

- Polar patrol:

- Self-heating film (-40℃ start-up)

- Phase change material temperature control (60℃ environment)

III.Three major technological evolution directions of lithium robot battery

1. Robot lithium battery material system innovation

| Type | advantage | application scenarios | Representative solutions |

|---|---|---|---|

| high nickel ternary | 350Wh/kg | humanoid robot | NCM811 |

| lithium iron phosphate | 5000 cycles | Industrial AGV | blade battery |

| solid-state battery | 400Wh/kg+no fire when punctured | Medical/Specialty | huineng20Ah |

2. Robot lithium battery intelligent BMS advanced

- Health degree prediction: LSTM neural network realizes SOH accuracy >96%

- Dynamic strategy adjustment:

- Cleaning robot floor tile mode reduces consumption by 20%

- Carpet mode power increase by 30%

- Wireless charging integration: under-dinner table charging plate realizes in-task energy supplementation

3. Revolutionary breakthrough in robot lithium battery structure

- Flexible battery: 5cm bending radius fit joint (LG Chem)

- Modular design: DJI agricultural machine “building block” battery pack

- Space magic:

- CTP technology volume utilization rate of 90%

- Weight reduction of 15% compared to traditional solutions

IV. Path to industrialization

1. Cost control: from $200/kWh to $150/kWh

- Large size of electric core: 4680 cylinders to reduce 12% structure cost

- Intelligent production line: AI quality inspection to improve the yield rate to 98%.

2. Safety Upgrade

- Ceramic coated diaphragm: temperature resistance 180℃ (Asahi Kasei)

- Fluorine electrolyte: ignition point increased by 80℃ (Xinzhoubang)

- Honeycomb protection: single fault isolation design

3. Standards and Recycling

- IEEE 1876 protocol: cross-brand compatibility of battery packs (replacement <5 minutes)

- Ladder Utilization:

- Robot Battery → Low-speed Electric Vehicle

- Metal Recycling Rate >90% (Grimme)

V. Future Integration Trends

1. Photovoltaic storage and charging integration:

PV charging for pole-flying plant protection machine improves range by 50%.

2. Solid-state battery commercialization:

Medical robots will be the first to carry it in 2026.

3. AI energy efficiency optimization:

neural network model based on 20,000 sets of data

Market Data: Global Li-ion Battery for Robotics to be $12B by 2025, with China accounting for 60% (SNE Research)