Lithium Battery Charge and Discharge Testing: The Key to Unlocking True Performance and Safety

Introduction: When selecting lithium batteries, the specification sheet is just the starting point. The true performance, reliability, and safety of a battery are all hidden in the rigorous lithium battery charge and discharge test data. As an engineer, I know that a battery that has not undergone comprehensive testing and verification is a gamble. This article will take you straight to the core of lithium battery testing, allowing you to see through the battery’s “true capabilities” at a glance when purchasing.

Lithium Batteries: The Foundation of Performance and Safety

Lithium batteries are the heart of modern devices. Their performance and safety directly determine the user experience, reputation, and even user safety of the end product. Therefore, comprehensive and precise charge/discharge testing is not merely theoretical laboratory work but a critical means to ensure that every battery you purchase can deliver stable performance and safe operation.

In-Depth Analysis: Practical Guide to Lithium-Ion Battery Charging and Discharging Testing

1. Charging Performance Exam: Efficiency vs. Endurance

Standard Charging Test in Action: Parameters are strictly set according to the battery specification sheet (typically current ranges from 0.2C to 1C). For example, for a 2000mAh battery, a 1C current is 2000mA. We monitor the voltage as it steadily rises to 4.2V and continue charging until the current drops to a pre-set threshold (e.g., 0.05C). This is the gold standard for evaluating a battery’s basic charging behavior and stability.

Fast Charging Capability Stress Test: The market demands speed? We simulate real-world fast charging scenarios by subjecting the battery to currents far exceeding the standard. This directly tests the battery’s ability to withstand fast charging and its thermal management capabilities. Engineer’s warning: While fast charging may be convenient, improper design can lead to severe overheating, electrode damage, and safety hazards. Reliable fast-charging batteries must pass rigorous testing!

The Temperature Battlefield: The Silent Killer of Charging Efficiency: Temperature is the battery’s “sensitive switch.” We conduct charging tests in extreme cold and heat environments. High temperatures accelerate internal reactions, shorten lifespan, and increase risks; low temperatures make the battery “stiff,” causing internal resistance to surge and charging efficiency to plummet. Understanding a battery’s temperature adaptability is critical for global product deployment.

2. Discharge Performance Insights: The Truth About Energy Output and Endurance

Capacity Measurement: No Fluff!: After fully charging the battery, discharge it at a specified current until it reaches the cutoff voltage (typically 2.5V-3.0V). Accurately measure the amount of electricity discharged to obtain the true usable capacity. This is the most critical indicator of a battery’s energy storage capability, putting an end to the “nominal capacity” wordplay.

Rate Discharge: Balancing Burst Power & Endurance: Discharge at high rates such as 0.5C, 1C, and 2C. Want to see how the battery performs under high-power demands (e.g., power tool startup, drone ascent)? Rate discharge testing provides the answers. At high rates, the rate of voltage drop and the effective capacity released are key observation points. A must-see for power battery purchasers!

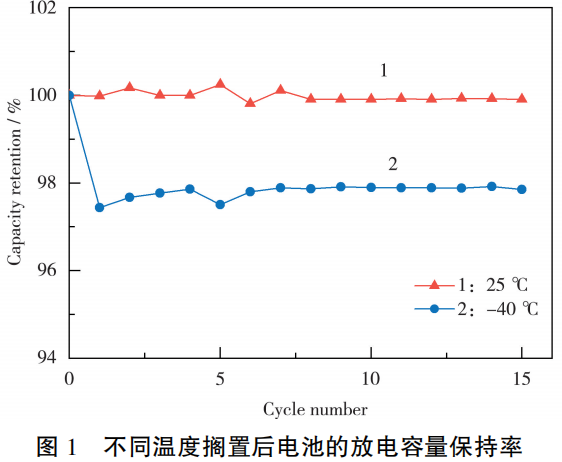

Cycle Stability: The Marathon of Endurance: Batteries are not disposable items! We perform hundreds or even thousands of charge-discharge cycles until their capacity degrades to a specific value (e.g., 80% of initial capacity). This is the ultimate test to reveal the long-term performance degradation patterns of batteries and predict their real-world lifespan. Looking to procure long-life batteries? This data is invaluable.

3. Comprehensive Performance Evaluation: The Ultimate Test Close to Real-World Conditions

Cycle Life Test: Time Tells the Truth: This is the pinnacle of cycle stability testing, involving continuous full charge-discharge cycles until capacity significantly degrades (typically to 80%). It comprehensively evaluates the cumulative impact of the entire charge-discharge process on the battery, making it the most authoritative indicator for assessing overall service life.

Pulse Discharge: Handling Sudden High Loads: Simulates scenarios with sudden high current demands, such as electric tools or starting power sources. Short-term high-current pulse discharge followed by recovery period cycles. Tests the battery’s voltage response speed, recovery capability, and stability under severe load fluctuations. A core basis for procurement decisions in dynamic load applications!

Simulated Load Testing: Mimicking Real Device “Appetite”: Using specialized equipment to simulate your product’s actual power consumption curve for charging and discharging. This provides a more precise prediction of the battery’s actual performance (endurance, temperature rise, efficiency) in your specific device compared to standard testing. The preferred testing solution for customized procurement or critical applications.

4. Safety Bottom Line Testing: The “High Voltage Line” That Cannot Be Tolerated

Short Circuit Testing: Extreme Thermal Runaway Simulation: An external short circuit is artificially created, which is extremely rigorous! Observe the battery’s response under catastrophic failure conditions: temperature rise rate, valve activation, fire, or explosion. This is the final line of defense for testing the battery’s passive safety design (such as CID, PTC) and thermal runaway suppression capabilities. A mandatory threshold for safe procurement!

Overcharge Testing: The Ultimate Test of Protection Mechanisms: Charge the battery far beyond its safe upper voltage limit. This tests whether the battery’s built-in protection circuits or inherent material safety performance can effectively prevent disasters (gas generation, swelling, thermal runaway). A reliable battery must withstand this test or be promptly interrupted by the protection mechanism.

Test Report: Your Procurement Decision Radar

Professional lithium battery charge and discharge testing generates massive amounts of data. Engineers’ in-depth analysis can reveal:

Performance Truth: Actual capacity, power capability (rate), energy efficiency, temperature adaptability.

Lifespan Prediction: Cycle lifespan, capacity retention rate, degradation pattern.

Safety Rating: Which safety tests have been passed? What is the safety margin?

Consistency Assessment: (For batch testing) Performance differences between cells.

Purchasing Pitfall Guide: Let the Data Speak

Does a certain battery model have poor rate discharge data? It may not be suitable for your electric motorcycle or outdoor energy storage project.

Does the cycle stability test show rapid capacity loss? Using this battery in shared devices or products that require frequent charging would be disastrous. Optimize your selection or ask the supplier to make improvements immediately!

Failed safety testing? Reject it outright! Safety is no small matter.

Engineer’s Conclusion: Testing is the cornerstone of trust.

Charging and discharging tests for lithium batteries are a rigorous, multidimensional system engineering process. They serve not only as a compass for research and development, but also as a “keen eye” for purchasers. Through comprehensive testing of charging, discharging, overall performance, and safety, we can accurately assess the true value of a battery and ensure that it safely, reliably, and durably releases energy in your products.

When purchasing lithium batteries, don’t just look at the specifications on paper! A thorough understanding of the charge and discharge test report is a crucial step in avoiding risks, ensuring quality, and winning the market. Choose suppliers who are transparent about their test data and can withstand rigorous verification.

Very nice article, just what I wantedd to find.