China’s Energy Storage Safety GB 44240-2024 Enters Mandatory Era

I. Standard Positioning: Historical Leap from “Recommended” to “Mandatory

On August 1, 2025, GB 44240-2024 (Safety Requirements for Lithium Batteries and Battery Packs for Electrical Energy Storage Systems) will be officially implemented as China’s first mandatory national standard for energy storage safety. The core breakthroughs of this standard, which is under the purview of the Ministry of Industry and Information Technology (MIIT), and led by the China Electronics Standardization Institute (CESI), lie in the following:

- Upgraded legal binding force: filling the mandatory regulatory gap in the new energy field, and prohibiting the listing of products that have not passed certification;

- Full life cycle control: covering the entire chain of core manufacturing → system integration → transportation and installation → operation, maintenance and recycling;

- Full coverage of application scenarios: applicable to telecommunication base stations, photovoltaic energy storage, and grid-level large-capacity energy storage (≥100kWh) scenarios, and so on.

Engineer insight: the new national standard of energy storage safety from the “enterprise self-selection” to “industry survival line”, forcing technology upgrades and poor quality production capacity out of the expected 30% of small and medium-sized manufacturers face elimination.

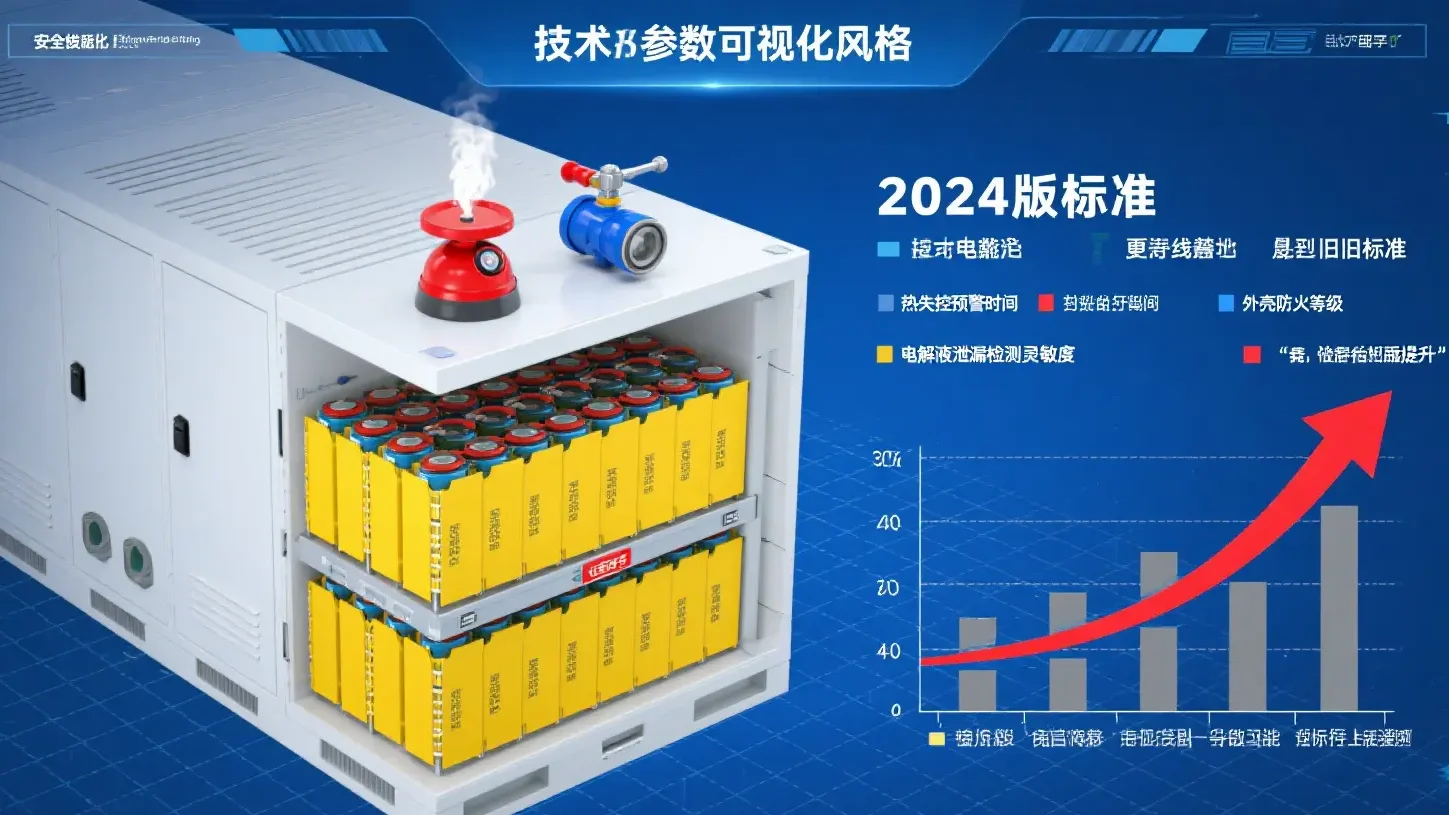

II. Technical breakthroughs: 23 extreme tests to define the new boundaries of safety

1. Core level – a global leader in harshness

Four new key tests have been added and existing items have been tightened, far exceeding international standards such as IEC 62619 and UL 1973:

| Test items | GB 44240-2024 requirements | Comparison of international standards | Engineering challenges |

|---|---|---|---|

| shallow prick test | A 5 mm steel needle is inserted to a depth of 10 mm or 30% of the battery thickness (whichever is greater). | IEC 62619 does not include this item. | Simulated transport impact causing internal short circuit |

| Overcharge test | 1.5 times pressure limit constant pressure charging for 1 hour + total duration of 1.5 hours | UL 1973 only requires charging to 1.5 times the pressure limit. | Testing the response accuracy and cathode stability of BMS |

| thermal runaway | After heating is triggered, the temperature rise rate at the monitoring point is ≥1°C/s for 3 seconds. | International standards do not specify quantitative temperature rise rate requirements. | Require the closed-cell temperature of the diaphragm to be ≤130°C. |

| forced discharge | After full discharge, reverse charge to -1 times the rated voltage. | Only Japanese standard JIS C8715 has similar requirements. | Preventing dissolution of negative electrode copper current collectors |

Subversive innovation:

- Thermal runaway diffusion test: 24 hours of observation after triggering the center core, requiring no flames, no shell rupture, and zero spread of fire;

- Overcharging safety redundancy: the total energy injection has increased by 30% compared to the old standard, forcing companies to optimize overcharging protection algorithms (e.g. multi-level voltage shutdown).

2.System level – integration of international standards and strengthened

Dual insurance mechanism: mandatory requirement of internal short circuit + thermal dispersion test are passed (IEC 62619 is one of the two options);

Environmental adaptability enhancement: vibration test simulating transportation conditions, shock acceleration ≥ 25G (the old version is only 15G);

Short-circuit protection response: external ≤ 100mΩ resistor short-circuit, the requirement of the protection circuit action time <1ms.

III. Enterprise Practice: How Head Manufacturers Overcome Technical Barriers

1. Certification progress and technical programs

The first batch of 21 products from 15 enterprises passed certification, and the common technical paths of head enterprises include:

- Ningde Times: self-healing electrolyte + nano-ceramic coated diaphragm, voltage fluctuation <5% in overcharging test;

- Vision Power: upgraded the national standard “shallow puncture” to penetrating puncture, short circuit current increased by 5 times, but still passed the test;

- BYD: cellular fireproofing compartment design, temperature diffusion delay after thermal runaway >2 hours.

2. Benchmark Cases of Extreme Test

Vision Power has completed six major tests under the witness of certification organizations:

- 5-meter drop (far exceeding the national standard of 1.2 meters);

- puncture instead of shallow puncture (steel needle completely penetrates the electric core);

- 5 times the national standard current high temperature outside short;

- UL 9540A combustion parry + NFPA 268 twice the flame power;

- the longest over-charging time in the world;

- no spreading for 24 hours after thermal runaway triggering.

Key support: 50GWh global delivery record of “0 fire, 0 open valve”, proving the reliability of design redundancy.

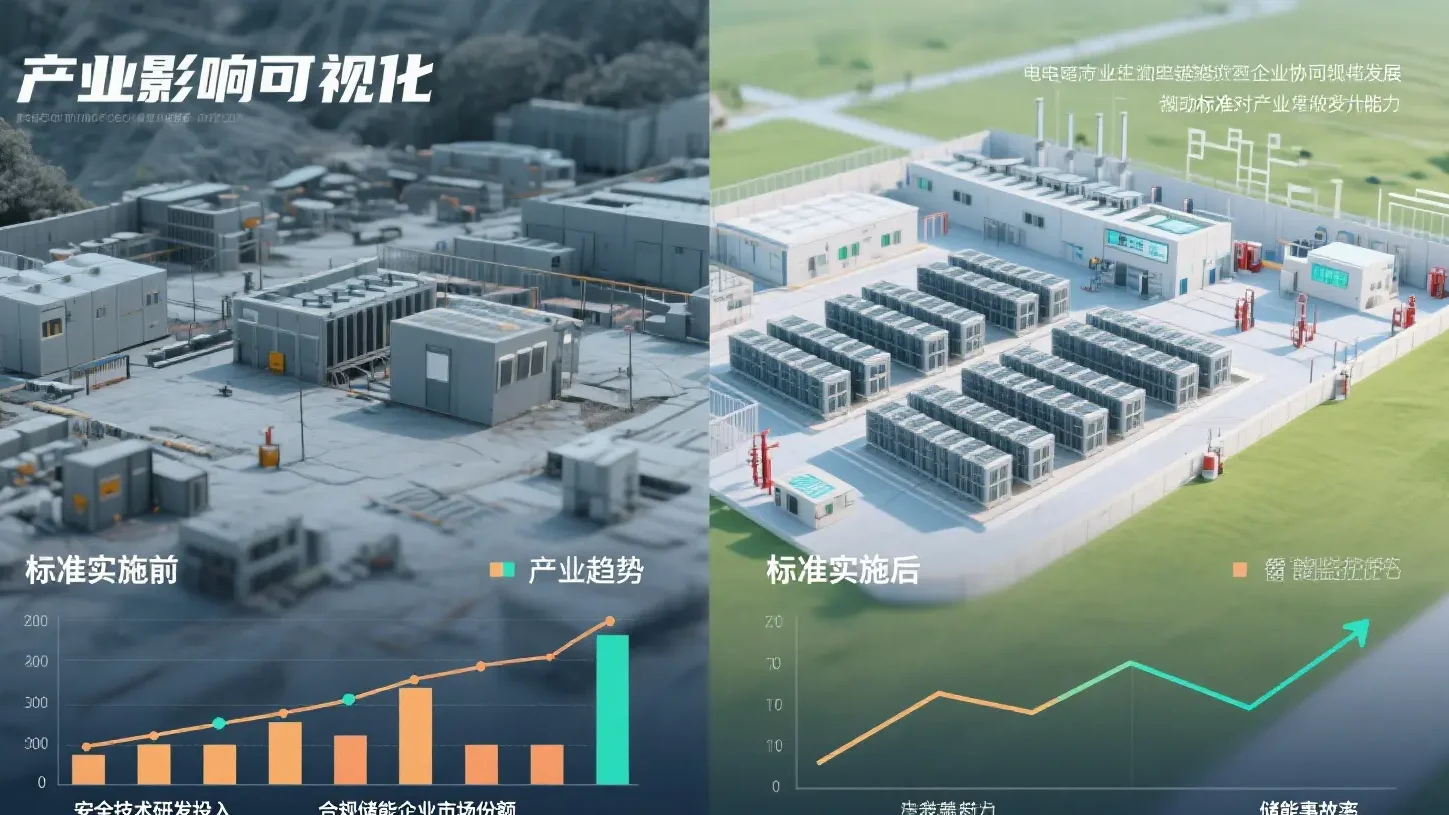

IV. Global Impact: Chinese Standards Reshape the International Rules of the Game

1. Three major paths of technology export

Market dominance: China’s energy storage batteries account for >90% of global shipments, and European and American projects need to comply with GB 44240 for procurement;

Insurance certification link: Lloyd’s and other organizations will incorporate GB 44240 into the premium calculation model, and the rate of certified products will be reduced by 15%;

Mutual Recognition of International Standards: CESI has signed mutual recognition agreements with UL and TÜV Rheinland, and multiple certificates can be issued to reduce the cost of going to sea.

2. China’s advantages over European and American standards

| dimension | GB 44240-2024 | IEC 62619 | UL 9540A |

|---|---|---|---|

| Test coverage | 23 full-scenario tests for battery cells and systems | Focus on system level (less cell testing) | Focus on thermal runaway propagation |

| severity | Overcharge duration: 1.5 hours, shallow prick mandatory project | Stop charging when the voltage reaches 1.5 times the limit. | No mechanical abuse testing |

| regulatory enforcement | Mandatory certification (prohibited from sale if not certified) | voluntary certification | voluntary certification |

V. Engineer’s Perspective: Compliance Strategies and Technology Trends

1. Short-term response recommendations

Material selection: monocrystalline high nickel for positive electrode (strong overcharge tolerance), ceramic coating for diaphragm (shallow puncture and internal shortening prevention);

BMS redundancy design: dual MCU architecture + millisecond overcharge shutdown (threshold accuracy ±0.5%);

thermal management innovation: multi-dimensional liquid cooling plate + phase change material (PCM) to ensure temperature gradient <5℃/min after thermal runaway.

2. Long-term technology evolution

- Solid-state battery breakthrough: sulfide electrolyte is naturally puncture-resistant (mass production by Vision Power in 2026);

- Intelligent Early Warning System: AI prediction based on early electrochemical fingerprints of internal short circuits (false alarm rate <0.1%);

- Test digitization: digital twin platform simulates extreme working conditions, shortening R&D cycle by 40%.

Assertion: GB 44240 will drive the energy storage industry from “cost per kWh” competition to “safety density” competition – with safety investment per kWh becoming a core competency .