The Impact of Low-Temperature Storage on Lithium Battery Performance

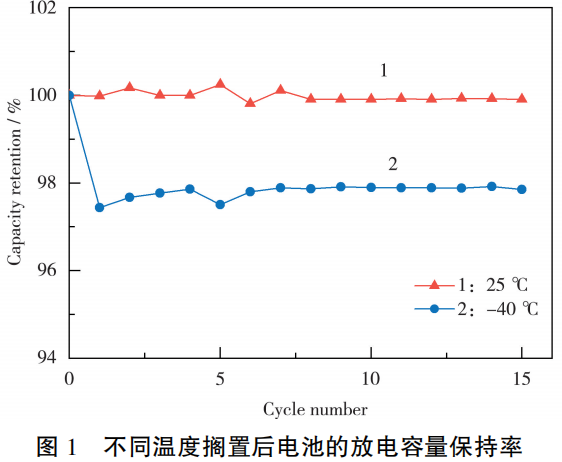

In extreme cold environments, the internal workings of a lithium-ion battery resemble a slow-moving symphony: ion migration is impeded, interfacial reactions become unbalanced, and performance ultimately declines sharply. As lithium battery engineers, we fully understand the effects of low-temperature storage on battery performance. In cold conditions, the insertion and extraction of lithium ions within the…