Blade Battery vs Li-ion Ternary Battery – Which is better?

Choosing the right battery technology according to specific application requirements is the optimal solution

As Li-ion battery technology engineers, we are often asked: “Which is better, blade battery or Li-ion ternary battery?” The answer is not simply good or bad, but depends on the specific application scenarios and performance requirements. This article will comprehensively analyze the characteristics of the two batteries from a technical point of view, to help you make a wise choice.

I. Core differences between blade batteries and lithium ternary batteries: material structure and technical features

Blade battery and ternary lithium battery material essential differences

Blade battery is essentially an innovative form of lithium iron phosphate battery, and the anode is made of lithium iron phosphate. The anode of ternary lithium battery is composed of lithium nickel cobalt manganese oxide (LNCMO) or lithium nickel cobalt aluminum oxide (LNCA). This difference in basic materials directly determines the different performance, safety and cost of the two.

Innovative structural design of blade battery and Li-ion ternary battery

The Blade Battery adopts a unique flat and narrow design, with a monomer length of up to 1 meter, a width of 10 centimeters and a thickness of less than 2 centimeters. This design allows it to be directly integrated into the battery pack, eliminating the need for intermediate modules and significantly improving space utilization.

Lithium ternary batteries, on the other hand, come in a variety of forms, with three common types: soft pack, cylindrical and square hard shell, adapting to different design needs and application scenarios.

II.The key performance parameters of the blade battery and lithium ternary battery comparison

In order to let you understand the difference between the two batteries more intuitively, the following is a comparison of the key technical parameters:

Table: Key Performance Comparison between Blade Battery and Li-ion Ternary Battery

| Performance indicators | Blade Battery | Ternary lithium battery |

|---|---|---|

| energy density | Approx. 140-160Wh/kg | 180-250Wh/kg |

| Cycle life | 3000-4500次(attenuation≤20%) | Approximately 2,000 |

| safety | Needle puncture test without open flame, no smoke, temperature 30-60 ° C | Warming over 500°C after needling, may burn violently |

| Low Temperature Performance | -20°C lower limit, significant low temperature attenuation | -30°C lower limit, better low temperature performance |

| costs | Lower (stabilization of material costs) | Higher (nickel, cobalt prices are volatile) |

| High temperature stability | Excellent (high temperature resistance) | Poor (risk of material decomposition at high temperatures) |

Energy Density and Range Performance

Li-ion ternary batteries have an obvious advantage in energy density, with mainstream products reaching 180Wh/kg, and Ningde Times Ni55 batteries even reaching 250Wh/kg, which means that in the same volume or weight, Li-ion ternary batteries are able to store more power and provide a longer range.

Blade battery improves the overall energy density of the battery pack through structural innovation. The CTP (Cell to Pack) module-less structure design eliminates the intermediate module link, resulting in a significant increase in space utilization, thus making up for the relatively low energy density of the cell itself.

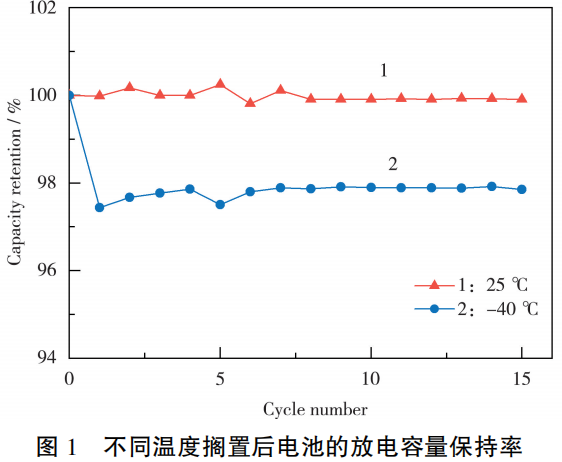

Cycle life and durability

Blade batteries have excellent cycle life, with more than 3,000 charging cycles, even up to 4,500 cycles, and less than 20% capacity degradation after 3,000 cycles. This means that a Blade battery can be used for 8-12 years with good performance based on one charge/discharge per day.

The cycle life of ternary lithium batteries is usually about 2000 times, and the capacity degradation is more obvious as time goes by. Measurement data shows that the capacity retention rate of Li-ion ternary battery is about 85% after 4 years of use, and may drop to about 80% after 5 years.

Safety performance comparison

Safety performance is the most obvious area of difference between the two batteries:

Blade batteries excel in safety. In the pinprick test, the blade battery has no open flame, no smoke, and the surface temperature is only 30-60℃. With its longer circuit, less heat production and faster heat dissipation, vehicles equipped with blade batteries have a significantly lower chance of triggering spontaneous combustion.

The thermal stability of ternary lithium batteries is relatively poor. When the battery is impacted or damaged, it instantly heats up more than 500°C after pinning and may burn violently. This is mainly due to the relatively poor chemical stability of lithium ternary materials, and the risk of material decomposition at high temperatures.

III. Blade battery and ternary lithium battery environmental adaptability analysis

Blade battery and lithium ternary battery temperature performance differences

Ternary lithium batteries perform better in low temperature environments, the lower limit of low temperature can reach -30℃, and the range decay is relatively small when used in cold areas. This makes ternary lithium batteries more suitable for applications in cold climate areas.

Blade batteries have relatively poor low-temperature performance, with a low-temperature lower limit of -20 ° C. Capacity degradation is more serious in low-temperature environments, and charging and discharging performance is also affected. This is a limitation of the inherent characteristics of the lithium iron phosphate material itself.

Blade battery and lithium ternary battery high temperature stability

Blade batteries perform well in high-temperature environments, with strong high-temperature resistance and good thermal stability. Measured data show that when the ambient temperature exceeds 45 ℃, the capacity loss of lithium ternary batteries is two times faster than lithium iron phosphate batteries.

Li-ion ternary batteries have the risk of material decomposition and poor thermal stability in high temperature environments, requiring more complex thermal management systems to ensure safety.

IV. Economy and Value Retention Analysis of Blade Batteries and Three Run Lithium Batteries

Blade battery and three transport lithium battery manufacturing costs and prices

Blade batteries have a significant cost advantage. Its manufacturing process is relatively simple, with low material and labor costs. In particular, the cost can be scaled down by about 30% relative to lithium ternary batteries. This is mainly due to the relatively stable price of lithium iron phosphate materials and the absence of expensive cobalt elements.

The higher cost of ternary lithium batteries is mainly due to the high and fluctuating prices of nickel and cobalt in the cathode material. This keeps the overall manufacturing cost of lithium ternary batteries high.

Blade and Triple Run Lithium Battery Retention and Long-Term Value

Battery type directly affects the vehicle’s value retention rate. Models equipped with blade batteries, such as the BYD Seagull, have achieved a high retention rate of 77.4% thanks to the integration of blade batteries and CTB battery body technology.

Overall, the value retention rate after three years in 2025 is about 44.2% for pure electric vehicles and 46.1% for plug-in hybrid models. Repair costs for lithium ternary battery models are typically three times higher than lithium iron phosphate models, which also affects their long-term economics.

V. Blade Battery and Three Run Lithium Battery Application Scenario Suggestions

Scenarios suitable for blade batteries

- Applications that emphasize safety: such as public transportation, school buses and other occasions that require high safety

- Long-term high-frequency use: areas that require long cycle life, such as cabs, logistics vehicles and other operational vehicles

- Projects with limited budgets: cost-sensitive applications, blade batteries offer better economy

- High-temperature environments: such as the southern region, the high-temperature stability of blade batteries is more advantageous

- Fixed-route applications: such as urban Fixed route applications: such as urban commuter vehicles with good charging facilities and low temperature performance requirements

Scenarios suitable for lithium ternary batteries

- High range requirements: high-end electric vehicle models that require maximum range

- Cold climate regions: such as northern regions, Li-ion ternary batteries have a clear advantage in low-temperature performance

- High-end consumer electronics: devices with high energy density requirements

- Performance-oriented models: high-end electric vehicle models pursuing acceleration and power output

- Weight-sensitive applications: such as drones, aircrafts and other occasions with very high weight requirements

For special applications such as custom drone battery packs, the advantages and disadvantages of both technologies need to be weighed according to specific needs. If safety and cycle life are important, blade batteries may be a better choice; if energy density and low-temperature performance are a priority, Li-ion ternary batteries may be more appropriate.

VI. Prospects for the development of blade battery and lithium ternary battery technologies

Evolution of Blade Battery

Blade battery technology is still evolving, and its energy density and low-temperature performance are being gradually improved through material improvements and structural optimization. BYD and other manufacturers continue to develop a new generation of blade batteries, aiming to further improve their performance shortcomings.

Improvement of ternary lithium battery

Ternary lithium battery technology is also progressing, with its safety and cycle life improved through material ratio optimization (e.g., high-nickel, low-cobalt formulations) and surface coating modification. At the same time, the advanced thermal management system also partially makes up for the thermal stability of the ternary lithium battery.

VII. Recommendations for use and maintenance

Regardless of the battery technology chosen, proper use and maintenance will extend battery life:

- Charging strategy: Avoid overcharging and discharging as much as possible, keeping the battery in the 20%-80% charge range is optimal

- Temperature management: Avoid prolonged use and storage of batteries in extreme temperatures

- Periodic calibration: Perform full charge/discharge cycles periodically to calibrate the battery management system

- Use original chargers: Ensure that the charging voltage and current are matched to the battery’s requirements

- Long-term storage: For long term storage, keeping the battery at around 50% charge is appropriate

VIII. Conclusion and selection recommendations

Blade batteries and Li-ion ternary batteries each have their own advantages, and there is no absolute “better” choice, only a solution that is better suited to a specific need:

- If safety, cycle life and cost are your primary considerations, blade batteries are a better choice.

- If high energy density, low temperature performance and range are more important to you, Li-ion ternary batteries may be more suitable.

For special applications such as custom drone battery packs, it is recommended to make a comprehensive evaluation based on the specific usage environment, performance requirements and budget constraints. In some cases, a hybrid battery system can even be considered, where different types of batteries are used in different parts of the vehicle to fully utilize their respective advantages.

As Li-ion battery technical engineers, we suggest consumers not to simply pursue a certain parameter index, but should consider the overall performance of the battery, the safety record, the manufacturer’s reputation and after-sales service system, to make a comprehensive evaluation and selection.