Battery Technology for Humanoid Robots: Solid State Technology Breakthroughs and the Rise of a $100 Billion Market

GAC GoMate robot equipped with all-solid-state batteries has a range of more than 6 hours, and energy consumption plummeted by 80%; Tesla Optimus has lost 15% of its weight due to solid-state batteries, and the space released allows joint freedom to be increased by 40% – 2025 has become a watershed year for the battery system of humanoid robots.

1, the energy bottleneck and the inevitable choice of solid-state batteries

The complex movements and intelligent decisions of humanoid robots pose a triple challenge to energy systems:

Endurance anxiety: the chest space is extremely limited, the energy density of traditional batteries (about 300Wh/kg) is approaching the theoretical limit, and the endurance of most products is only 1-2 hours, which is far lower than that of more than 4 hours as required by commercialization scenarios. GAC’s third-generation GoMate robot has upgraded its range to 6 hours with an all-solid-state battery and reduced energy consumption by 80%, overturning the industry benchmark.

Safety Risks: In industrial inspection and disaster rescue scenarios, collisions and high temperatures may trigger liquid battery leakage or explosion. Chery’s tests show that even if a corner of the solid-state battery is cut off, it can still be charged and discharged normally without the risk of fire.

Environmental adaptability: Polar scientific research or desert operations need to withstand -40 ℃ to 80 ℃ temperature domain. The capacity of traditional lithium batteries decreases by more than 50% at low temperatures, while Nandu Power’s solid-state batteries realize stable discharge in -30℃ environment, guaranteeing mission execution around the clock.

Four major intrinsic advantages of solid-state batteries:

Energy density jump: sulfide system reaches 400-500Wh/kg (mass-produced by VNTech in 2025)

Intrinsic safety: solid-state electrolyte isolates the risk of liquid leakage and thermal runaway

Cycle life doubled: Huawei’s solution supports 5,000 cycles (about 20 years)

Structural adaptability: customizable shaped dimensions optimize the distribution of robots’ center of gravity

2.Technical breakthroughs and mass production: from lab to commercialization

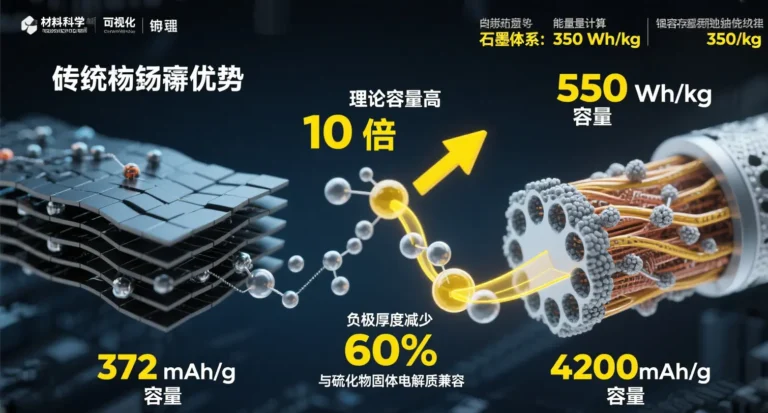

Material system innovation drives performance leap

Electrolyte technology routes are differentiated:

Sulfide system: Vonergy 60Ah products with energy density of 400-500Wh/kg, small batch delivery planned for the end of 2025, ionic conductivity of 1.2mS/cm;

Oxide-polymer composite: Tsing Tao Energy’s energy density exceeds 550Wh/kg, suitable for humanoid robots’ joint modules;

Halide integrated cathode: CAS team develops iron-based materials, energy density of 725.6Wh/kg, energy density of 725.6Wh/kg, energy density of 725.6Wh/kg, energy density of 725.6Wh/kg. 725.6Wh/kg, automatic repair of electrode cracks during charging and discharging.

Interfacial impedance attack: solid-solid interfacial impedance up to 80-100Ω-cm² is the core obstacle to mass production. By building a lithium lanthanum zirconium oxide (LLZO) buffer layer through atomic layer deposition (ALD) technology, the impedance has been reduced to less than 40Ω-cm², and the charging and discharging efficiency has been increased by 30%.

Industrialization process is fully accelerated

2025 will be the first year of solid state battery mass production:

Capacity layout: new domestic signed project investment of more than 10 billion yuan, Qingtao energy planning 10GWh capacity, Nandu power Hangzhou base up to 5GWh;

cost optimization: semi-solid-state battery cost down to 1 yuan / Wh, full solid-state due to precious metal doping is still up to 3.5 yuan / Wh, Dow technology development of rare metal-free sulfur-silver germanium ore electrolyte, the goal of the compression of 2 yuan / Wh;

standard leading: China’s “full solid-state Standard lead: China’s “all-solid-state battery determination method” (2025) the world’s first, requiring 120 ℃ drying 6 hours after the weight loss rate <1%, for the industry to set up an authoritative yardstick.

3. Deep Expansion of Application Scenarios: From Factories to Homes

Industrial scenarios: balancing safety and performance

Ubitus Walker S operates continuously for 8 hours on an automobile assembly line, relying on the 4C fast-charging capability of Tsing Tao Energy’s solid-state batteries (20%-80% SOC in just 12 minutes). Industrial scenarios are the first areas where solid-state batteries have been deployed due to the high requirements for range and safety, accounting for 68% of current applications.

Specialty Operations: Conquering Extreme Environments

Polar scientific research: the battery pack developed by Harbin University supports stable discharge at -40°C, and passes the explosion-proof flame retardant and high-frequency vibration test;

Disaster Rescue: after Unitree Go2, the AI robot dog of Yushu Technology, switches to a solid-state battery, its range is extended from 3 hours to 5 hours, and it is adapted to the high-temperature environment of the ruins.

Home service: the game of cost and safety

Family robots need to wait for the cost of the whole machine to drop below 100,000 yuan per unit. Huawei ecological chain enterprises through the Hongmeng system to realize the “Pangu big model + Quafu robot” of energy and AI synergy, the goal of 2026 to enter a million families.

4. Differentiated layout of innovative enterprises

Chinese enterprises have formed five types of differentiated strategic camps in the field of solid-state batteries:

Electrolyte material leaders

Shanghai Scrubber: joint research institute with Chinese Academy of Sciences, oxide electrolyte energy density of 480Wh/kg, cut into Huawei robot supply chain;

Dow Technology: low impedance sulfide electrolyte certified by Tesla Optimus supplier, pushing energy density to break through 400Wh/kg.

System integration innovators

Del: launched “battery+drive” integrated module, adapted to the high dynamic response of humanoid robots, and the German team cooperated with the development of thermal management technology;

LiMo lithium energy: directly hit the three major pain points – high-energy 21700 batteries (energy density of 300 Wh/kg) to solve the range anxiety; high energy density 21700 batteries (energy density of 300 Wh/kg) to solve the range anxiety; Dow Technology: impedance sulfide electrolyte was certified by Tesla Optimus supplier to promote energy density exceeding 400 Wh/kg. kg) to solve range anxiety; full lug design reduces internal resistance by 74%; 46137 cylindrical battery passes the pin-prick no-fire test.

Scenario Definer

Qingtao Energy: No. 1 in patent quantity in China, core supplier of GoMate robot for Guangzhou Automobile;

Vonergy Technology: second-generation semi-solid-state batteries were fixed by U.S. eVTOL and humanoid robot customers, and advancing the head enterprises to send samples.

Lightweight solution provider

Blonde Technologies develops composite battery shells, integrates the whole machine to reduce weight by 30%, and lays out thermal management materials to address heat dissipation needs.

Eco-level integrator

Shanghai Electric relies on the background of central enterprises, integration of solid-state battery production line and robotics business, self-developed inspection robot has been applied solid-state battery.

5、Challenges and Future: Industrialization Attack Direction

Current technical bottlenecks

Cost and resource constraints: All-solid-state batteries have high costs due to the vacuum vapor deposition process, and the dependence of lithium resources on foreign countries is over 60%. Solutions include:

Closed-loop recycling: GLM has realized a nickel-cobalt-manganese recycling rate of over 95%, and the electrolyte-free feature of solid-state batteries reduces the recycling pollution by 90%;

Sodium resource substitution: Meilian New Material mass-produces Prussian Blue anode materials to reduce the dependence on lithium.

Process complexity: sulfide electrolyte is easy to produce toxic hydrogen sulfide, and the yield of oxide coating is only 70%. Shanghai Scrubber improves sulfide air stability by 300% through nano-coating technology.

Policy and standard empowerment

The Ministry of Industry and Information Technology “humanoid robot innovation and development guidance” clearly support solid-state battery R & D, Shenzhen, the installation of enterprises to give 30% subsidies; the urgent need to establish the industrial robot battery explosion-proof standards and home scene safety certification system.

The next five years of technological evolution

2026: semi-solid-state batteries in industrial robots penetration rate of more than 40%, the family scene to test the water;

2028: all-solid-state cost down to 1.8 yuan / Wh, humanoid robots endurance breakthrough 10 hours;

2030: the global solid-state battery shipments of 614.1GWh, the field of humanoid robots accounted for 35%.

When Qingtao Energy’s 10GWh production line is running around the clock, and when YWL’s dense energy system supports robots to complete high-load dance moves, this solid-state battery-driven revolution is redefining the boundaries of humanoid robots’ capabilities.

According to EVTank’s forecast, the global humanoid robot market will exceed 1.5 trillion yuan in 2030, and Chinese companies have already occupied the high point of the energy system by virtue of their 70% share of solid-state battery patents. The essence of technological breakthroughs is to change safety and performance from single-choice questions to mandatory questions, and to upgrade human expectations of machines from “being able to act” to “existence without perception” – Energy-as-a-service (Energy-as-a-service). (Energy-as-a-Service) era has come.