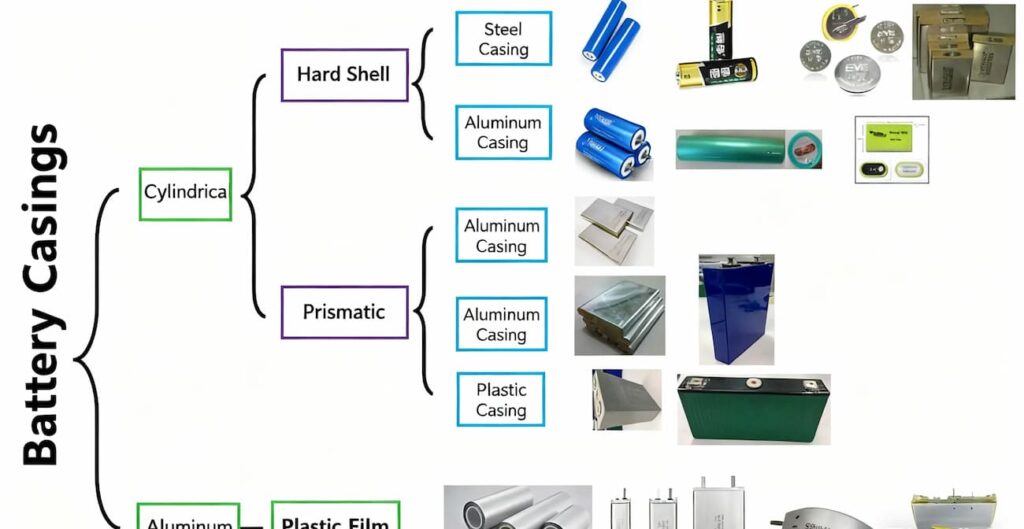

Lithium Battery Enclosure Selection for 2025

Battery enclosures are not merely protective casings; they are critical components that influence energy density, safety performance, and thermal management. Choosing the right lithium battery enclosure for 2025 is of paramount importance!

As lithium battery engineers, we must deeply understand the technical characteristics and design considerations of different shaped lithium battery packaging enclosures. As a key component of the battery system, the lithium battery enclosure provides fixation and full sealing for the internal electrochemical system. The structural strength and thermal dissipation capabilities of the casing directly determine the battery’s operational capacity and safety.

As application demands continue to rise, alongside utilizing high-energy-density electrode materials, reducing the mass of structural casing components while enhancing their strength and thermal performance has become a vital pathway for improving overall battery performance. Different types of battery casings exhibit distinct characteristics in material selection, manufacturing processes, and performance, making them suitable for diverse application scenarios.

I. Steel Casing for Lithium Batteries: The Classic Choice for Cylindrical Batteries

Cylindrical lithium batteries predominantly utilize steel with strong physical stability as their casing material. To prevent oxidation of the steel casing by the battery’s cathode active material, manufacturers typically employ nickel plating to protect the iron substrate.

Currently, specialized BDCK cold-rolled material (B: Baosteel; DCK: Battery Shell) is primarily used for cylindrical battery steel casings in China. This battery steel, mass-produced exclusively by Baosteel domestically, has gradually replaced imported steel. The battery casing caps utilize SPCC ordinary cold-rolled material.

The manufacturing process for steel-cased lithium batteries is mature, ensuring high consistency and excellent resistance to internal pressure. The standard GB/T 34212-2017 “Cold-Rolled Steel for Battery Cases” governs this process, having taken effect on June 1, 2018.

However, steel cases present certain limitations: their heavier weight results in lower system energy density after cell assembly and less-than-optimal space utilization. These factors restrict the application of steel cases in scenarios demanding high energy density.

II. Lithium Battery Aluminum Alloy Enclosures: Balancing Lightweight Design and High Thermal Dissipation

Aluminum alloy materials offer significant advantages for power battery enclosures: with a density only one-third that of steel, they provide substantial weight reduction potential; their thermal conductivity is five times that of steel, enhancing battery thermal management; and they absorb twice the energy per unit weight than steel, featuring excellent ductility and high plasticity.

Aluminum alloy also exhibits excellent weldability and manufacturability, superior casting properties enabling diverse shapes, along with strong corrosion resistance and ease of recycling. These characteristics make aluminum alloy an ideal choice for power battery casings.

The national standard GB/T 33824-2017 “Aluminum and Aluminum Alloy Plates and Strips for Covers and Caps of New Energy Batteries” took effect on December 1, 2017, standardizing the quality requirements for aluminum materials used in new energy batteries.

Material Selection and Performance Requirements

Power battery casings typically utilize 3003 aluminum-manganese alloy, which must meet multiple requirements: sufficient strength (e.g., a brand requires 200 MPa tensile strength); impact resistance with minimal fracture and leakage risk; corrosion resistance for extended service life; excellent thermal stability for sustained operation at 100°C; superior thermal conductivity (180 W·m⁻¹·K⁻¹); and outstanding weldability.

Structural Design and Reinforcement Techniques

To enhance aluminum casing performance, manufacturers employ multiple reinforcement techniques. A high-pressure-resistant square battery aluminum casing features multiple equidistantly spaced longitudinal and transverse stiffeners at the top, bottom, left, and right ends of its outer surface, significantly boosting surface strength.

The four internal corners of the battery casing incorporate thickened sections and rounded corners. This design not only fortifies the edges and corners but also dissipates stress at these points, minimizing deformation.

The square bottom-connected lithium battery-specific casing utilizes high-purity aluminum (GB1050.1060.1070) and alloy aluminum (GB3003 aluminum) materials. Advanced grain refinement technology is applied, organically combining rolling processing with extrusion forming techniques to ensure the casing’s density and dimensional consistency.

External dimensions and thickness tolerances are maintained within 0.03-0.05mm, offering advantages over conventional welded-bottom aluminum cases, including higher strength and leak-proof performance.

III. Aluminum-Plastic Film for Lithium Battery Cases: The Flexible Choice for Pouch Cells

Pouch cells utilize aluminum-plastic film as their encapsulation material, characterized by flexible dimensional adjustments, low cost, and high energy density per cell. However, pouch cells also present challenges such as poor mechanical strength, difficult sealing processes, complex module structures, challenging thermal management design, and difficulties in integrating explosion-proof devices.

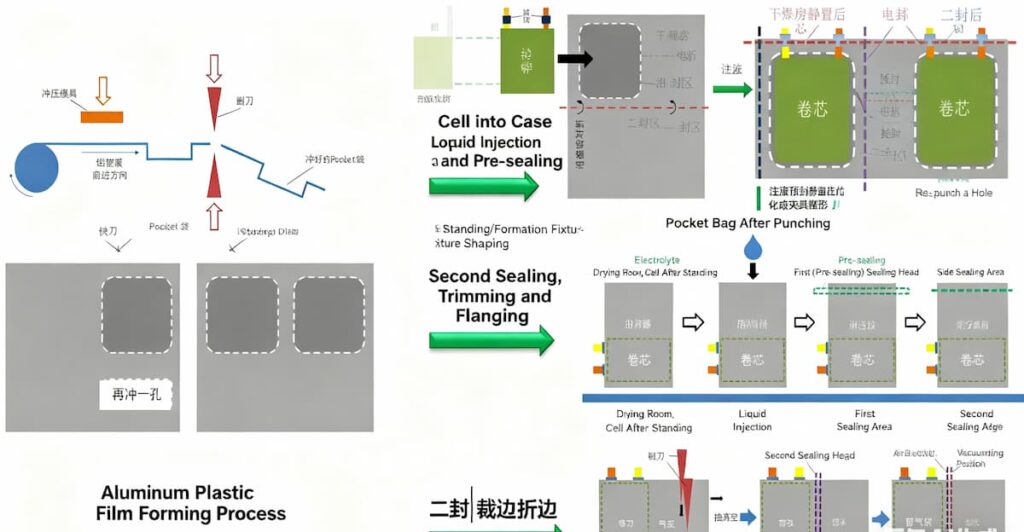

Forming Processes and Technological Breakthroughs

The forming methods for pouch battery casings involve precision processes: thin sheet materials (aluminum-plastic film, stainless steel, or titanium) used for casing fabrication are temperature-adjusted to the working temperature (between room temperature and the metal’s recrystallization temperature or the plastic material’s glass transition temperature).

Fluid pressure differentials are used to apply uniform forming pressure to the sheet material through a two-stage process: the first stage preforms a part with an initial depth, forming at least one compensation section at the bottom; the second stage completes the final part with a deeper second depth.

This process enables the manufacture of shells with high aspect ratios, promotes uniform deformation of the sheet material, and utilizes the compensation section to counteract corner deformation at the bottom of the final part. It maintains a reduction ratio below 30% while preventing cracking, thereby enhancing product yield.

IV. Performance Comparison and Application Scenarios of Lithium Battery Enclosures

The three primary battery enclosure types each possess distinct advantages, disadvantages, and suitable applications:

V. Structural Innovation and Future Development

Battery casing technology continues to evolve through innovation. Heat-dissipating lithium-ion battery square plastic casings utilize polypropylene (PP) material, offering resistance to electrolyte corrosion. The casing design features a tapered transition from the upper opening to a flat surface, resolving issues of poor sealing and aesthetic defects during battery sealing while enhancing ventilation and heat dissipation during battery assembly.

Reinforcing ribs are integrated into the front, rear, side, and bottom surfaces of the casing. These ribs enhance structural strength and ventilation while simultaneously reducing the overall weight of the battery casing.

Reinforced casing designs for pouch batteries are also advancing. One reinforced casing for a pouch power battery pack comprises a lid and a tray. The tray features a main body for holding the pouch batteries and a locating section at its top to secure the lid.

Support plates are positioned at all four corners of the main body to bear the lid. A recessed section with protrusions is formed in the center of the lid. The lid’s four corners are secured to the support plates via screws. This simple structure facilitates disassembly and assembly while enhancing the enclosure’s strength and safety margin.