How will fast charging of lithium iron phosphate (LFP) batteries be realized in 2025?

“Charge for 10 minutes, range of 400 kilometers”-behind this kind of publicity slogan, in fact, is a sophisticated game between materials science and engineering limits.

From the perspective of engineering development, a single battery system is often difficult to achieve high energy density, high safety, wide temperature range performance, low cost and excellent conductivity. There is a rigorous logic of trade-offs behind this: strengthening one characteristic often requires compromises on the other.

At Auto Shanghai 2025, an Azera owner asked Li Bin: “Will frequent overcharging really halve battery life?” Li Bin confessed, “Whether we can provide 10-year warranty for overcharging users is still a common challenge for the industry.” This question and answer reveals the core contradiction in the popularization process of new energy vehicles – replenishment efficiency and battery life, can we really get both? As 60% of the global power battery market share of the “cost-effective king”, lithium iron phosphate (LFP) battery fast charging bottleneck, is the focus of the current technology.

I. Fast charging and life: a pair of natural contradictions

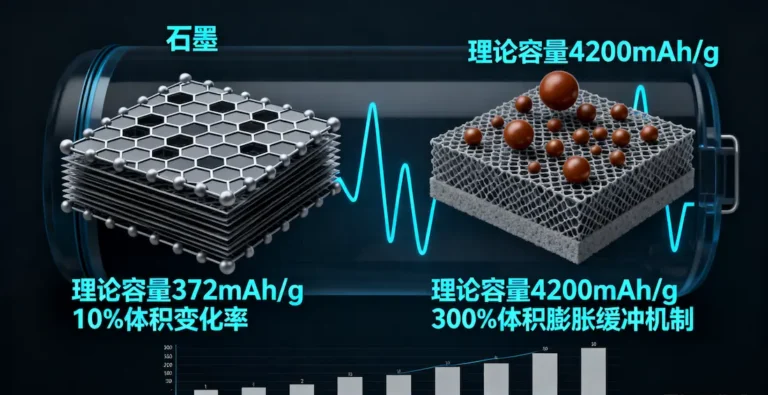

Fast charging damages the nature of the battery, lies in the challenge of the physical limit of lithium ion migration. When the current density reaches 5-8 times that of slow charging, the embedded behavior of lithium ions in the anode graphite layer changes from “orderly arrangement” to “violent impact”, triggering a threefold chain reaction:

- Structural deformation: the graphite layer spacing is forced to widen from 0.335 nm to 0.348 nm, and the capacity retention rate decreases by about 5.5% after 500 cycles;

- Chemical side reaction: electrolyte decomposition is accelerated above 45°C, and SEI membrane reconstruction speed is increased by 3 times, resulting in irreversible loss of active lithium;

- Lithium dendrite growth: uneven deposition of ions may form dendrites, piercing the diaphragm and triggering internal short circuits.

Real data reveals the grim reality:

- Three-year average capacity degradation rate of 18.7% for internet cars (fast charging utilization > 70%), much higher than 9.3% for private cars (<30% fast charging);

- In the lab, a single 4C overcharge cycle can result in a 10-15% reduction in battery life.

II. LFP’s “fast charging dilemma”: material intrinsic limitations and engineering challenges

Lithium iron phosphate (LFP) has become a representative of safety and long life due to the high stability of its olivine structure (volume change of only 6.8%), high thermal runaway temperature (270°C), and low lithium precipitation tendency (only 23% of NCM). However, its fast charging performance is constrained by three major shortcomings:

1. Low intrinsic conductivity:

The lithium ion diffusion coefficient is only about 10-¹⁴-10-¹⁶ cm²/s, which is 3-4 orders of magnitude lower than that of ternary materials;

Insufficient electronic conductivity, which needs to rely on carbon coating and nanosizing treatment. resulting in a cost increase of about 20%.

2. Slow two-phase reaction kinetics:

Early theories suggested that LiFePO₄/FePO₄ two-phase interfacial barriers existed in the charging and discharging of LFP, which hindered the ion transport. The latest synchrotron radiation study shows that the LixFePO₄ transition phase is actually formed under fast charging conditions, and the uneven lithium embedding causes local stress concentration.

3. Insufficient precision of SOC estimation:

The flat voltage platform (3.2-3.3 V) leads to an error of ±5% in the estimation of the state of charge (SOC), which is easy to be misjudged by the BMS system and increases the risk of overcharging.

4. Physical upper limit constraints:

Four key parameters support the theoretical upper limit of LFP fast charging to be about 5.2C, while the actual material is significantly behind in all these indicators. Any attempt to go beyond this physical limit will face the challenges of heat buildup, lithium precipitation risk, and rapidly rising costs.

In-depth analysis of key parameters:

1.Li-ion diffusion capacity (D):

- The Li-ion diffusion coefficient in ternary materials (NCM) is about 10-¹¹-10-¹² cm²/s, while LFP is only 10-¹⁴ -10-¹⁶ cm²/s.

- Li-ion diffusion in ternary materials is 1,000 to 10,000 times faster than in LFPs due to their layered structure that provides two-dimensional migration channels, while the one-dimensional tunneling of LFPs is more susceptible to obstruction.

2. Electronic conductivity (σ):

- The intrinsic conductivity of ternary materials is about 10-⁵ S/cm, while that of LFP without modification is only about 10-⁹ S/cm, which is still significantly low even after optimization with carbon coating.

- The high internal resistance leads to significant ohmic polarization during fast charging, and Joule heat becomes one of the main heat sources.

3. Interfacial reactivity (i₀):

- The exchange current density of ternary materials can reach 10-⁴ A/cm², while that of LFP is only about 10-⁶ A/cm².

- To achieve the same charging rate, LFPs require a higher overpotential, which leads to a more pronounced heat of polarization.

4 Operating voltage (E°):

- The average voltage of the ternary material is about 3.7 V, while the LFP is 3.3 V.

- For the same power, the LFP needs to be subjected to a higher current, which further exacerbates the heat generation and side reactions.

III. Technological breakthroughs: from material modification to intelligent system management

Material level: interface functionalization regulation

The research team of Beijing Institute of Technology realizes dual effects by constructing a nitrogen-based functional interface layer:

Utilizing N-Li affinity to promote ion migration under high magnification, the electrode expansion rate is reduced by 40%;

Stabilized CEI membrane is formed at low magnification, and active lithium loss is reduced by 63%.

(The results were published in Advanced Functional Materials, 2025)

System level: three tools to optimize fast charging

Golden charging interval (20%-80% SOC): electrode polarization is reduced by 50% in this interval, e.g., Tesla supercharging can reach 250 kW at this stage;

Dynamic power regulation: e.g., BYD blade batteries control inter-cell differences within 0.02 V through millisecond voltage monitoring;

Temperature co-management: preheating at -10°C to 25°C can Improve fast charging efficiency by 35% and reduce decay rate by 30%.

IV. Industrial Practice: Three Evolutionary Paths of LFP Fast Charging

Material iteration:

- Ningde Times 4C Shenxing battery: using graphite surface fast ion ring, cycle life exceeds 3,000 times;

- Tesla 4680 LFP: using FePO₄@C core-shell structure, realizing 60% charging in 24 minutes.

Structural innovations:

such as BYD honeycomb electrodes and porous fluid collectors from Phono Technology, which increase heat dissipation efficiency by 300%.

Intelligent O&M:

Xiaopeng XNGP system predicts battery degradation with the help of AI and warns of abnormalities 6 months in advance, with an accuracy rate of 92%.

V. User Guide: How to extend battery life while using fast charging?

Charging strategy suggestion:

- Avoid using overcharging at <10% or >90% of charge, when the level of damage may increase by 70%;

- Slow charging once a month to complete cell equalization can restore 1.5-3% of effective capacity.

Temperature management:

- Prefer night-time charging in summer, with liquid-cooled piles to control the temperature at 25-35°C;

- Preheat the battery to 15°C or more before charging in winter.

Read the warranty terms:

- Pay attention to identify the terms of “lifetime warranty does not include attenuation”, only 23% of vehicle owners fully understand the details;

- High-frequency overcharging users (e.g., online cars) need to confirm the annual overcharging frequency limit, and some brands reject the warranty if it exceeds 200 times/year.

VI. Outlook: the balance of technology before the solid-state battery

The current LFP fast charging technology has gradually moved from “inevitable damage” to “controlled loss”. With the promotion of 800V high-voltage platform and the continuous progress of interface engineering, the target of 1.2% annual average degradation rate has become feasible.

The ultimate solution still points to solid-state batteries – their solid-state electrolytes are expected to eliminate the dendrite problem at all, minimizing the impact of overcharging on lifespan!