2025 Lithium Battery Forced Discharge Test Methods

I. Engineering significance and safety boundary of lithium battery forced discharge test

Lithium battery Forced Discharge Test (Forced Discharge Test) is the core means to assess the safety of lithium batteries in the state of deep overdischarge, and its necessity stems from:

1.Simulation of real risks:

equipment protection circuit failure, unbalanced multi-string battery packs leading to single over-discharge;

2.reveals the failure mechanism:

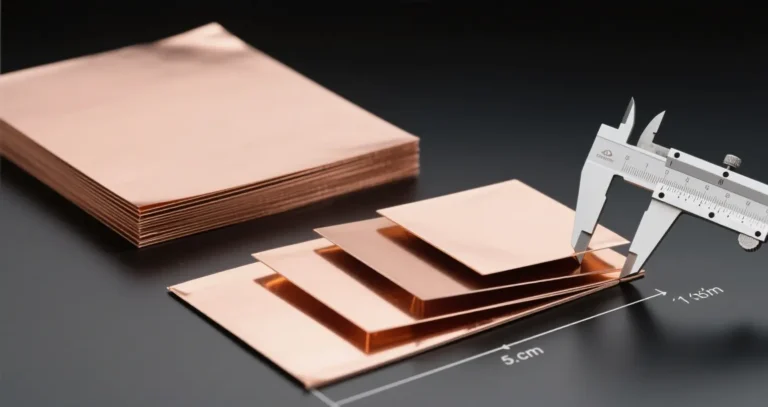

Negative electrode copper foil dissolution (potential <0V vs. Li/Li⁺) → triggering an internal short-circuit;

Electrolyte decomposition produces H₂ → gas expansion, case rupture;

Positive electrode active material structure collapse → precursor of thermal runaway.

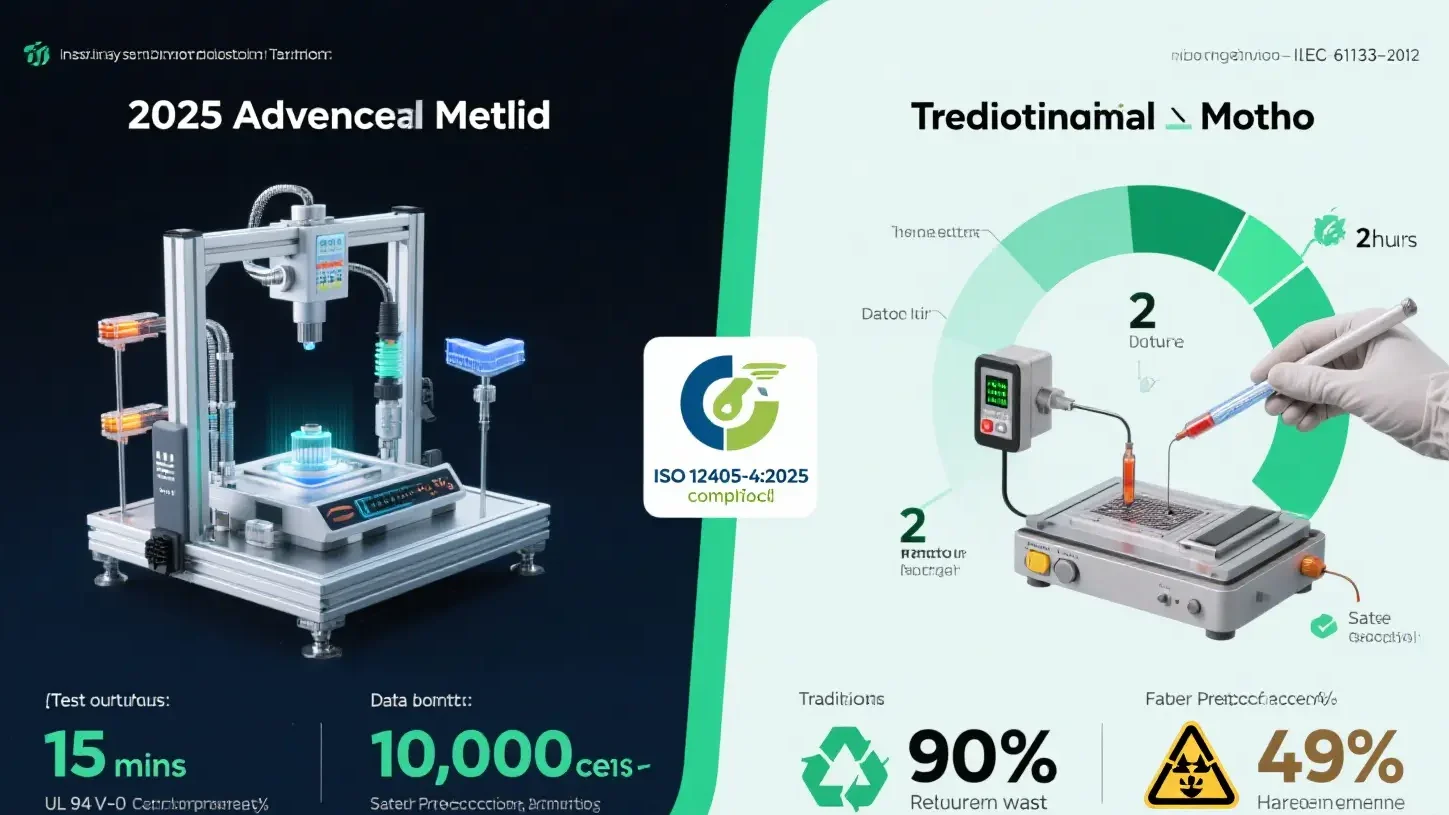

3.International certification just required:

IEC 62133-2, UN38.3 (air transportation), GB 31241 (portable battery) mandatory requirements.

Engineer’s warning: Batteries that do not pass this test have hidden safety defects that could lead to catastrophic consequences in energy storage/power applications.

II. Electrochemical Analysis of Lithium Battery Testing Principles and Failure Mechanisms

When the voltage of lithium battery is forced down to below 0V (usually -1 times the rated voltage), irreversible damage occurs to the electrodes:

| electrodes | chemical reaction | safety risk | Inspection mark |

|---|---|---|---|

| cathode | Cu → Cu²⁺ + 2e⁻(Copper collector fluid dissolution) | Dendrite growth → Separator perforation → Internal short circuit | Voltage drop, DC internal resistance ↑50% |

2EC + 2e⁻ → C₂H₄ + 2CH₃OCO₂⁻(gas production) | Shell swelling, pressure relief valve activated | Pressure sensor readings >5kPa | |

| anodal | LiCoO₂ → Co₃O₄ + O₂(Oxygen release) | Catalytic electrolytic combustion → Thermal runaway | Infrared thermal imager shows >150℃ |

III. Standardized test procedure (IEC 62133-2:2017 clause 8.3.9)

1. Test conditions

Test object: single cell (to be fully charged to the upper limit voltage)

Discharge parameters:

Series 12V DC power supply (to compensate for circuit voltage drop)

Discharge current = Maximum discharge current declared by the manufacturer (Id_max)

Discharge time = Rated capacity (Ah) / Id_max (A)

Termination condition: Setting time reached or cell voltage ≤ -1x rated voltage

2. Equipment Requirements and Accuracy

| equipment | key parameters | engineering significance |

|---|---|---|

| Programmable DC power supply | Voltage range ≥15V, current ≥1.5 times Id_max | Provide stable backflow voltage |

| High-precision electronic load | Range coverage Id_max, voltage sampling accuracy ±0.05% | Precise control of discharge current |

| data acquisition system | Sampling rate ≥10Hz, number of channels ≥4 (V, I, T, P) | Capture voltage drop/temperature rise inflection points |

| Safety protection box | Explosion-proof rating IP6X, pressure relief channel ≥0.1m² | Ensuring the safety of testers |

3. Lithium Battery wiring scheme (4-wire remote compensation)

[DC Power+] —-(Force+)—- [Cell+]

[DC Power-] —-(Force-)—- [Electronic Load+]

[Electronic Load-] —————– [Cell-]

[Data Acquisition] —-(Sense+)—- [Cell+]

—-(Sense-) —- [Cell-]

Key point: Force line and Sense line are separated to eliminate cable impedance error and ensure voltage sampling accuracy ±1mV.

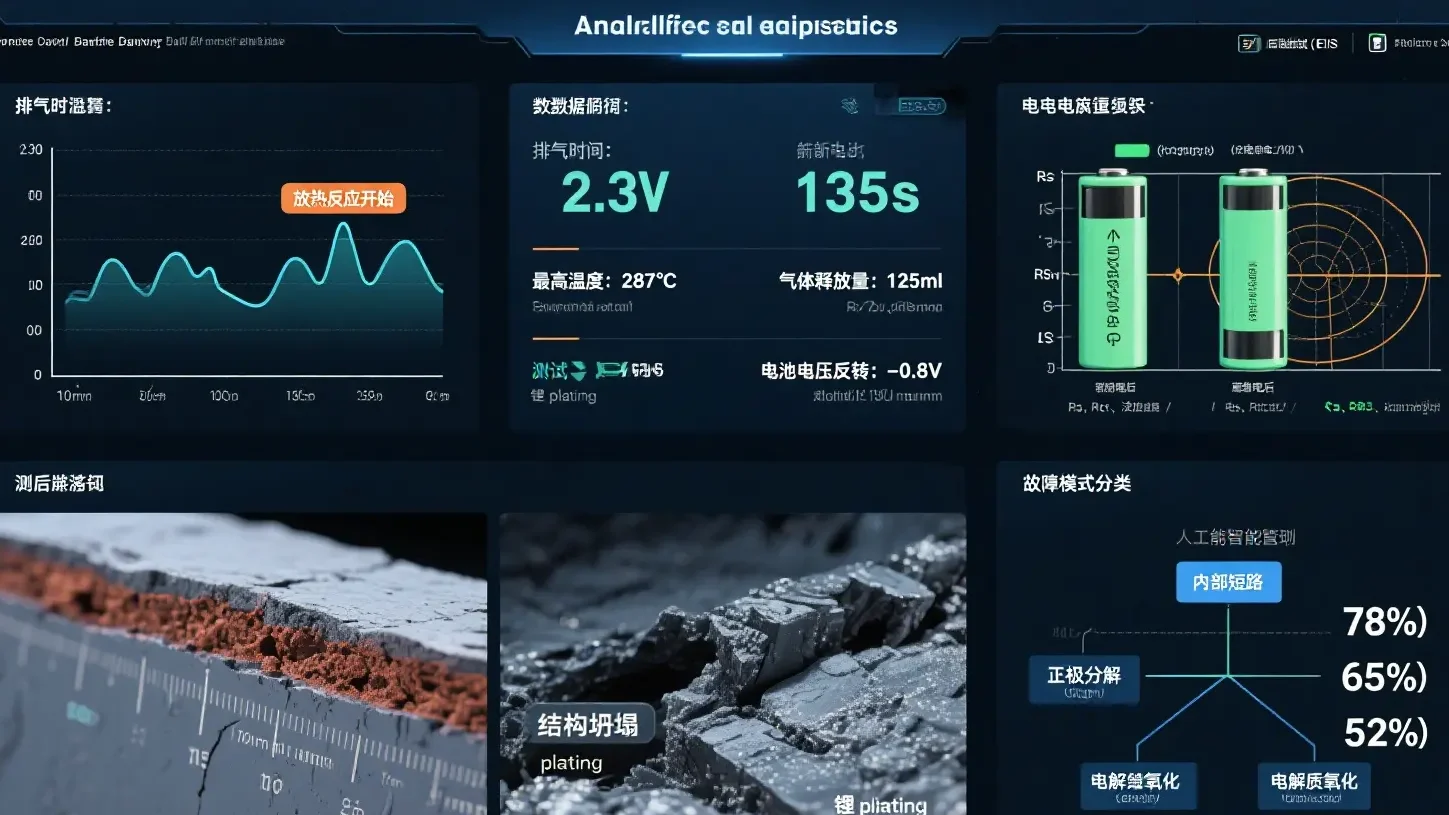

IV. Lithium Battery Test Execution and Failure Judgment

1. Pre-processing:

- battery cells complete charging and discharging cycles for 3 times according to IEC 62133 requirements;

2. Test monitoring:

- Real-time recording of voltage, current, surface temperature and pressure inside the case;

- High-speed camera to capture the process of pressure relief/ejection (frame rate ≥1000fps);

3. Passing standards:

- No fire or explosion;

- No rupture of the case (crack length <3mm);

- Voltage ≥0V after test (measured after 24 hours of standing);

- Quality loss ≤50% (only applicable to batteries containing electrolyte).

V. Engineering Practice: Key Techniques to Avoid Misjudgment in Lithium Battery

1. Current accuracy calibration:

Use shunt + 6.5-digit multimeter to calibrate the electronic load online (error <±0.5%);

2. Voltage sampling optimization:

Sense wire is directly welded to the core lugs to avoid contact resistance interference;

3. Failure root cause analysis:

If the test fails, disassemble the battery cell for SEM/EDS analysis to confirm copper dendrite or diaphragm melt-through traces;

4. Upgraded safety protection:

test chamber integrates an inert gas injection system (N₂ flow rate >10L/min) to inhibit combustion reactions.

VI. Cutting-edge testing technology: from passive detection to active warning

1. In-situ impedance analysis (EIS):

injects a 1kHz AC signal during the discharge process to monitor the sudden change in charge transfer impedance (Rct) (early warning of internal short circuit);

2. Acoustic Emission Monitoring:

captures >100kHz high frequency acoustic waves from copper dendrite growth (sensitivity -60dB);

3. Multi-physics field simulation:

COMSOL-based coupled electrical-thermal-force modeling to predict thermal runaway thresholds for over-discharge (error <5%).

Engineer’s Insight: Forced discharge testing is not only a compliance threshold, but also a design tool to optimize the intrinsic safety of batteries – with failure analysis inversely guiding material selection (e.g., corrosion-resistant coating collectors).