Square vs soft pack vs cylindrical lithium three technology differences

Introduction: In the core field of power batteries, square batteries, soft pack batteries and cylindrical batteries constitute a triad of current technology routes. Tesla’s cylindrical batteries, BYD’s square batteries, and Azalea’s soft pack batteries each represent a comprehensive trade-off between energy density, safety boundaries, system integration and cost structure. In this paper, we will analyze the structural characteristics, performance differences, technological evolution paths and their suitability in different application scenarios of the three mainstream battery forms of square vs. soft pack vs. cylindrical lithium-ion, providing professional insights into the industry’s technology selection.

I.Structural Analysis: Morphology Determines Basic Characteristics

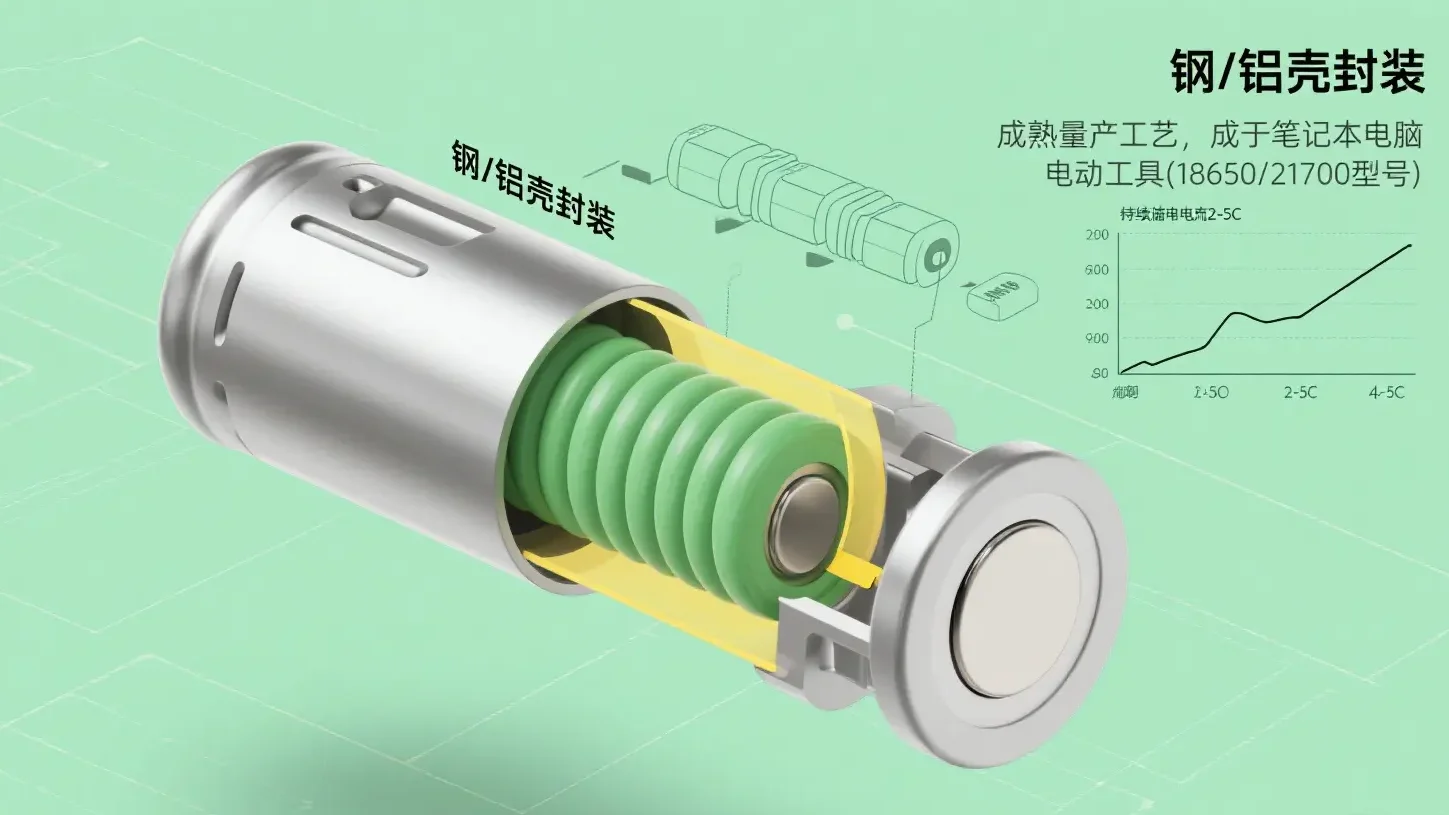

Cylindrical Cell:

Structural Characteristics: Standardized metal casing package, internal wound electrode structure (positive/negative/diaphragm spiral winding). Typical models are 18650, 21700, 4680 (numbers represent diameter and height in mm).

Core Advantage: High degree of standardization of production process, high versatility of production lines, which is conducive to cost reduction on a large scale (e.g. Tesla’s Superfactory model).

Key Challenges: Limited single cell capacity, high energy demand depends on precise integration of multiple cells (e.g., Model S with over 7,000 cells), and stringent requirements for BMS (Battery Management System).

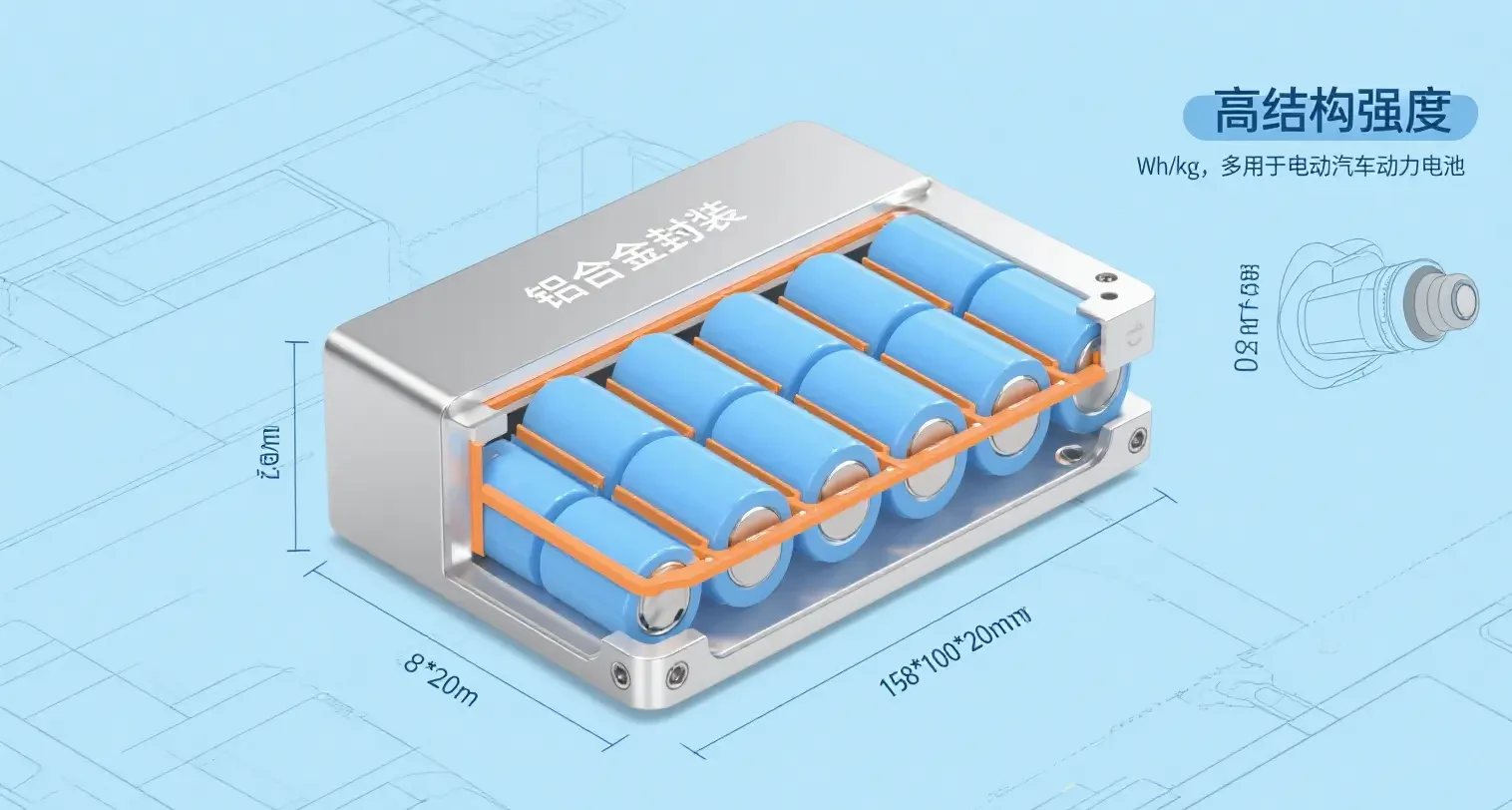

Prismatic Cell:

Features: Rigid metal (steel/aluminum) or plastic housing, with internal wound or better space-efficient stacked electrodes. Representative technologies: BYD Blade Battery, Ningde Times CTP (Cell to Pack).

Core advantages: Strong structural rigidity, excellent resistance to mechanical impact (extrusion, puncture), high efficiency of spatial arrangement, easy to realize system structure integration (e.g. CTB/Cell to Body).

Key Challenge: The weight of the shell usually results in a lower mass energy density than that of a soft pack battery for the same capacity.

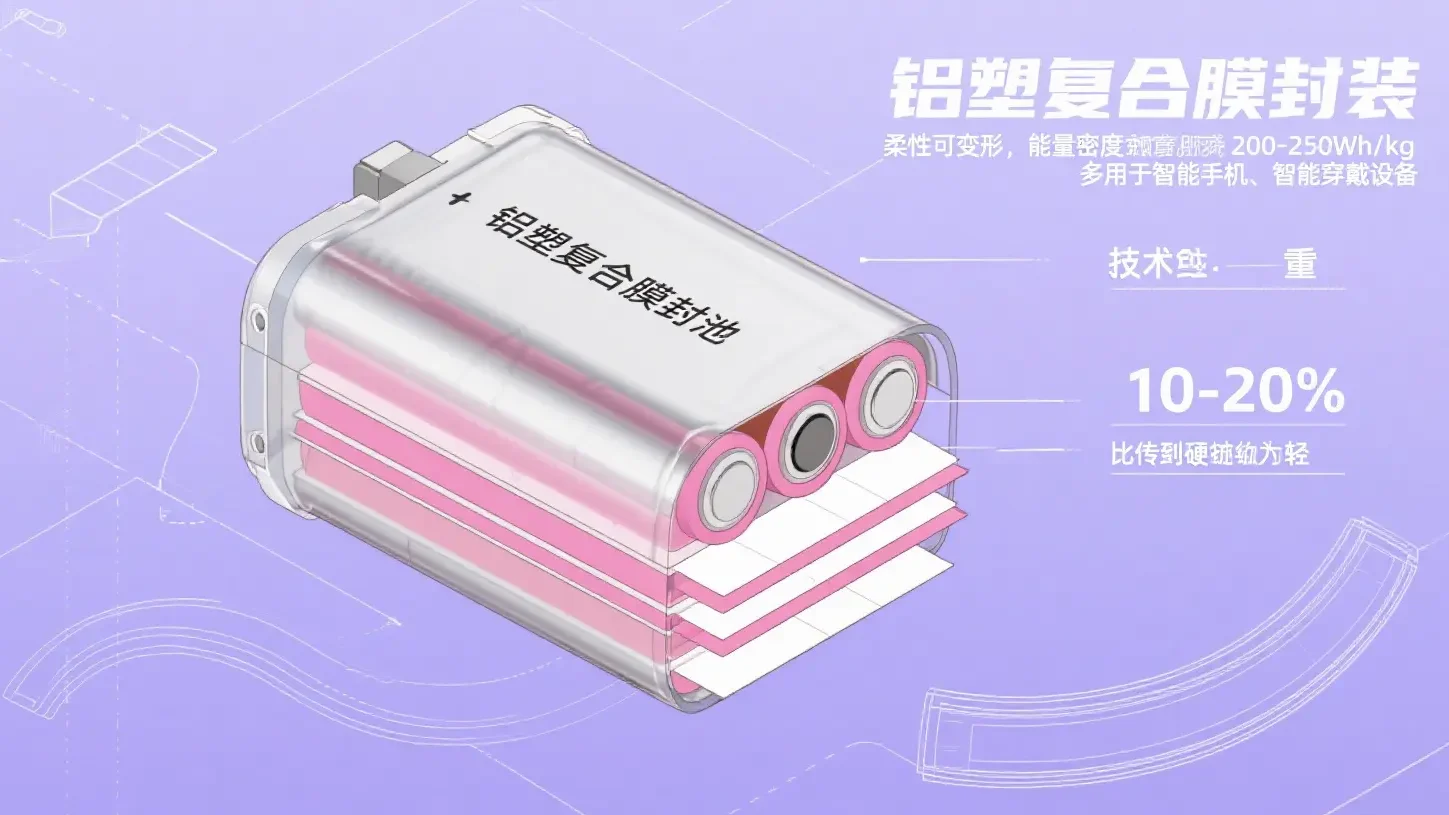

Pouch Cell:

Features: Lightweight aluminum-plastic film flexible encapsulation with flexible internal winding or stacking.

Core Advantages: Encapsulation material is the lightest, mass-energy density is usually ahead (10%-20% higher than square), and flexible form facilitates heterogeneous space design.

Key Challenges: Long-term cycling has a swelling effect, requiring buffer space and constraints in the module/pack design; Aluminum composite film requires high mechanical protection; production environment (cleanliness) is demanding.

II. Core Performance Dimensions: Range, Safety and Lifespan

1. Energy Density & Range.

- With the lightest package, flexible pack batteries maintain the lead in mass energy density (e.g., Ulai ET7 achieves 1000km+ range).

- Cylindrical batteries continue to catch up with larger batteries (e.g. 4680 cells), with energy density exceeding the 300 Wh/kg target (Tesla Model 3 800km range).

- Square batteries (especially LiFePO4 LFP route) are in the middle of the energy density range, but are optimizing system level energy density through CTP/CTC technology.

2. Safety.

- Square cells (especially LFP + hard-shell) excel in mechanical abuse (e.g., pin-prick test) and have good thermal stability.

- Cylindrical batteries have significantly reduced internal resistance and short-circuit risk through structural innovations (e.g., 4680’s lugless/full lug design), enhancing monomer safety.

- Soft pack batteries have relatively high risk of thermal runaway under the ternary system, which depends on excellent thermal management design and module constraint mechanism.

3. Cycle Life & Longevity.

- The hard shell structure of square battery can effectively inhibit electrode deformation, and the cycle life of LFP square battery is excellent (e.g., blade battery >2000 cycles @80% SOH).

- Cylindrical batteries have good system-level cycle life (~1500 cycles) due to single-cell fault isolation by BMS.

- Soft pack batteries are affected by the expansion effect, and the capacity retention after long-term cycling is relatively challenging, requiring optimization of electrode materials and encapsulation processes.

III. Technology Evolution & Cost

Cylindrical batteries:

Trend: Toward large size (46xx), combined with induction lug technology to increase power, energy density and reduce internal resistance/heat generation.

Cost: Unit manufacturing cost advantage due to high standardization and high line speeds. System level integration costs (soldering, connectors, BMS complexity) are a challenge.

Square cells:

Trend: LFP material popularity, deep integration of CTP/CTC/CTB technology to maximize space utilization and system energy density. Increased penetration of stacking process.

Cost: high material utilization, the shell can act as part of the structural components, system integration cost advantage. But the customization of size brings certain production line flexibility cost.

Soft pack battery:

Trend: Optimize expansion force management (module design, materials), explore higher energy density material system (high nickel, silicon carbon anode).

Cost: Aluminum film cost, strict production environment requirements, complex module/pack design push up manufacturing cost. The optimization of vehicle energy consumption brought by its light weight is a potential value point.

IV.The choice of technology routes for car companies: analysis of engineering logic

Tesla (Cylinder):

Core logic: Maximize the scale effect and supply chain flexibility brought by standardization (multi-supplier).

Technical support: industry-leading BMS capability, solving multi-cell management problems; 4680 + electrodeless lugs continue to improve monomer performance.

BYD (Square-LFP):

Core logic: Vertical integration advantages (material, cell, pack, vehicle), giving full play to the safety and cost advantages of LFP square battery.

Technical support: innovation in blade battery structure improves Pack space utilization; CTB technology realizes deep integration between battery pack and body chassis, improving vehicle rigidity and space.

Azera, etc. (soft pack):

Core logic: Pursuing extreme energy density to meet the demand for long range in high-end models; optimizing the vehicle layout (e.g., flat chassis) by using flexible forms.

Technical support: application of high-performance ternary materials; advanced thermal management system and module constraint design to meet the challenge of expansion.

V. Outlook of future pattern: driven by scenarios and technological innovation

1. Short-term (3-5 years): parallel development, scenario differentiation

Economy/mainstream models: Square-LFP batteries (especially CTP/CTC technology) dominate the market by virtue of their comprehensive advantages in cost, safety and life span.

Middle and high-end performance models: fierce competition between large cylindrical (4680, etc.) and high-performance soft packs, with cylindrical relying on scale + system management and soft pack relying on energy density.

Flagship/long-range models: soft pack batteries (high nickel ternary/silicon based) are still attractive, relying on advances in thermal management and expansion control technology.

2. Medium-term variable: Solid-State Battery

Solid-state electrolytes will reshape the logic of form selection:

Square/soft pack: easier to adapt to solid-state electrolyte layers (brittle, pressure requirements). Square hard shell facilitates sealing and stacking pressure; soft pack lightweight advantage continues.

Cylindrical: Solid electrolyte uniformity and stress at curved interfaces needs to be addressed. Its tandem advantage may diminish in solid-state systems.

The form of victory or defeat depends on the maturity of solid-state electrolyte mass production and its process compatibility with different packaging forms.

3. Long-term Trend: Deep Scenario Adaptation

Commercial vehicles (public transportation/heavy trucks): Square-LFP is still the first choice (durability, safety, low cost).

Domestic passenger cars: square (LFP/MN3) and large cylindrical are the main routes, depending on the platform strategy and cost control ability of the automaker.

High-end passenger cars/sports cars: soft pack solid state or high specific energy soft pack (pursuing ultimate light weight and energy density).

Specific applications (energy storage back-up/light electric appliances): Cylindrical batteries (standardization, replaceability) still have a market.

Conclusion: Adaptability is king, technology is foundation

There is no absolute “mainstream choice”, the three major forms of square batteries, flexible pack batteries and cylindrical batteries will continue to evolve and develop in their most suitable application scenarios:

- The core of cylindrical battery is to drive down the cost through standardization and manufacturing revolution, and rely on strong BMS and system integration capabilities to overcome the challenges of monomer integration.

- The core strengths of square cells are structural strength, safety (especially LFP), and the potential for deeper integration with the vehicle (CTx), which is the benchmark for scale and reliability.

- The core competencies of flexible pack batteries are the highest mass energy density and design flexibility, and their future lies in overcoming expansion management challenges and improving manufacturing economics.

The commercialization of next-generation technologies, such as solid-state batteries, will be a key variable that could reshape the competitive landscape. For engineers, an in-depth understanding of the physical properties of different forms, material system compatibility, manufacturing processes, and system integration requirements will enable them to make optimal technology choices for specific applications. Continuous focus on material innovations (e.g., LiMnFePO4 LMFP, ultra-high nickel, silicon anode), structural innovations (multi-electrode, CTx), and process innovations (large castings, dry electrodes) will be the key to grasping future trends.