Breaking the Deadlock on Lithium-Ion Battery Safety and Performance: A Deep Dive into the Core Value of Overhang Design

Introduction: Lithium dendrites—the “ticking time bomb” hidden within lithium-ion batteries—are the primary culprits behind thermal runaway, safety risks, and reduced battery lifespan. How can we address this issue at its source? Overhang battery design, as a critical tool in the arsenal of battery engineers, directly determines the safety boundaries and performance limits of batteries. This article will provide a professional analysis of the mysteries, value, and trade-offs of Overhang battery design, helping you make more precise and safer procurement decisions in the complex battery market.

I. Overhang Design: The First Line of Defense for Safety

Imagine that during charging and discharging, lithium ions surge toward the negative electrode (typically graphite) like a tidal wave. If the “coastline” (anode capacity) is not long enough, some of the “tide” (lithium ions) has nowhere to go and crystallizes on the anode surface, forming dangerous lithium dendrites. These sharp crystals, like steel needles, can easily pierce the separator, causing internal short circuits, and ultimately leading to thermal runaway or even fire and explosion—a nightmare scenario for all battery applications.

The core mission of the Overhang battery design is to reserve a safe buffer zone for these “unaccommodated” lithium ions! It achieves this by designing an area on the edge of the negative electrode (anode) that extends beyond the coverage range of the positive electrode (cathode), artificially expanding the “effective coastline” of the negative electrode. This carefully calculated “excess zone” (i.e., the Overhang region) serves as the critical buffer zone for absorbing excess lithium ions and preventing their precipitation at the edges or surfaces to form lithium dendrites, thereby significantly enhancing the inherent safety of the battery.

II. Seven Key Elements of Overhang Design and Their Practical Impact

1. The cornerstone of safety:

Core value: The core contribution of the Overhang design lies in significantly reducing the risk of lithium dendrite formation. A larger negative electrode area means lower local current density and lithium ion deposition driving force, fundamentally reducing the possibility of lithium metal precipitation on the negative electrode (especially at the edges) and strengthening the battery’s safety defenses.

Pain point solution: Directly addresses the core concerns of purchasers—battery safety and potential thermal runaway risks.

2. Golden Ratio: N/P Ratio (Negative-to-Positive Capacity Ratio):

Professional Definition: N/P Ratio = Reversible Capacity of Negative Electrode / Reversible Capacity of Positive Electrode. This is the quantitative core of Overhang design!

Golden Range: Industry experience indicates that the N/P ratio is typically carefully set between 1.03 and 1.5. Why?

>1.0: Ensures the negative electrode has sufficient “seating capacity” to accommodate all lithium ions released from the positive electrode, preventing “overflow” (lithium plating).

Not too high: Avoids excessive redundancy in the negative electrode, which can lead to reduced energy density and increased costs (excess negative electrode material also costs money!).

Procurement Insights: Understanding the N/P ratio claimed by suppliers is a key indicator for assessing their battery safety margin and design rationality. Too low (close to 1.0) poses high risks, while too high may result in poor cost-effectiveness.

3. The Art of Dimensions:

Basic Principle: To achieve effective overhang, the dimensions (length and width) of the negative electrode sheet must be larger than those of the positive electrode sheet. This provides critical edge buffer space.

Balancing Act: Larger dimensions are not always better. Excessively large overhang areas:

Displace internal battery space, reducing volumetric energy density.

Increase the proportion of inactive materials (copper foil, conductive agents, binders), reducing weight energy density.

May exacerbate side reactions.

Engineer’s Recommendation: Design must be optimized based on battery size (e.g., cylindrical, prismatic, pouch), application requirements (energy density/power density needs), and target N/P ratio.

4. Performance trade-offs: Initial efficiency and capacity:

Observed phenomenon: Increasing the negative electrode area (overhang) typically results in:

A slight decrease in initial coulombic efficiency (ICE): During the first charge cycle, the total amount of active lithium consumed in forming the SEI film increases (because the larger negative electrode surface area requires more SEI film coverage).

Increased charging capacity, but reduced discharging capacity: During the first charge, more lithium ions are consumed during SEI formation, resulting in a reduction in the actual available lithium ions (discharging capacity).

Root Cause Analysis: This is related to SEI film formation and the slight decomposition of the electrolyte on the larger negative electrode surface. This is a controllable, minor trade-off that must be accepted in pursuit of higher safety.

5. The trade-off of cycle life:

Potential impact: Excessive negative electrode area (especially in the overhang region) may pose challenges in long-term cycling:

More significant capacity degradation: The continuous growth and repair of the SEI film during cycling will continuously consume active lithium and electrolyte. A larger negative electrode surface area means that the “base” for this consumption is larger, which may lead to accelerated loss of active lithium.

Increased electrolyte consumption.

Engineering Perspective: This once again highlights the importance of balance. Design must strike the optimal balance between safety margins and long cycle life. Optimizing electrolyte formulations and charging strategies offers room for improvement in this regard.

6. The unignorable “side leakage”: lateral diffusion of lithium:

Professional Insights: During charging and discharging, lithium ions not only embed/extract in the thickness direction (vertical) of the electrode but also exhibit lateral diffusion within the electrode plane.

Impact on Overhang: This diffusion affects the local lithium ion concentration distribution in the overhang region. This effect must be considered during design to ensure the overhang region continues to effectively function as a “buffer pool” during dynamic processes, preventing local lithium plating. Advanced simulation modeling is critical in this process.

7. Core strategies for optimization design:

Size matching: Minimize the size of the overhang area (i.e., strive for the positive and negative electrode sheet sizes to be as close as possible) while meeting N/P ratio safety requirements. This is key to balancing safety, energy density, and cycle life.

Synergistic optimization:

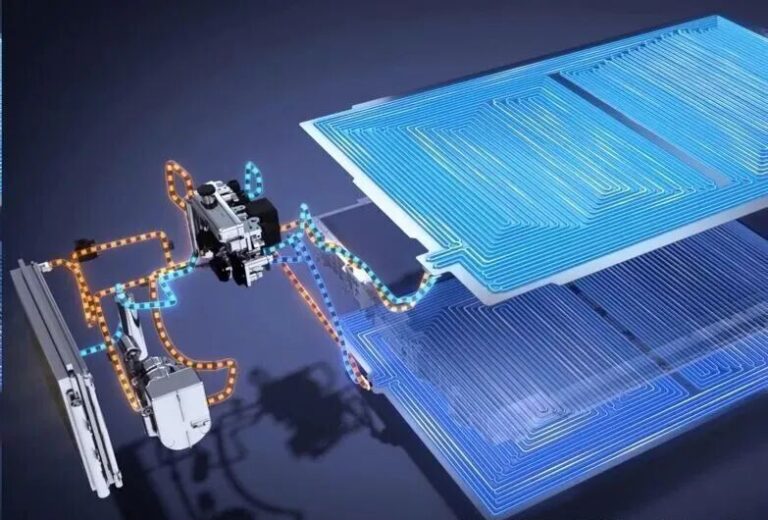

Electrolyte formulation: Develop electrolytes with excellent film-forming additives, high stability, and low consumption to mitigate the impact of SEI.

Charging Strategy: Optimize charging current (C-rate) and cutoff voltage, especially at low temperatures or high SOC, to avoid exacerbating lithium plating risks. An intelligent BMS is critical for this.

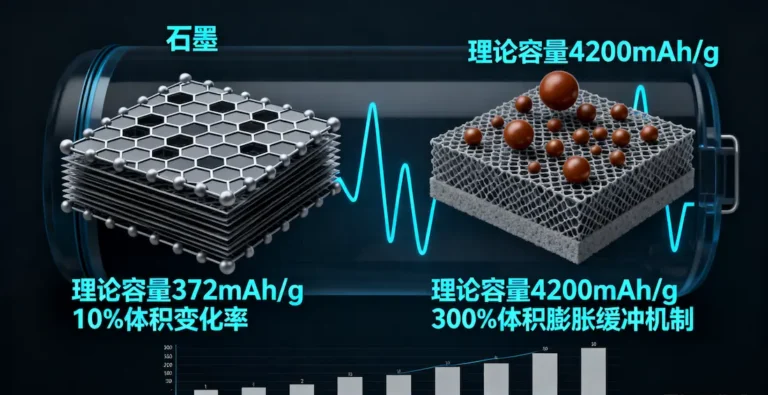

Material Selection: Explore higher-capacity anode materials (such as silicon-based) that can achieve the required capacity in a smaller area/volume, indirectly optimizing the overhang design space.

III. Conclusion: The Perfect Balance Between Safety and Performance

Overhang design is by no means a simple matter of adding or subtracting dimensions. It is a precision engineering process in which lithium battery engineers seek the optimal solution among multiple objectives, including safety, energy density, cycle life, and cost.

Core Value: It is an indispensable design approach for suppressing lithium dendrite growth, enhancing battery intrinsic safety, and ensuring user safety and property protection.

Key Factors: Precise control of the N/P ratio (within the optimal range of 1.03–1.5), rational design of the anode size, and a thorough understanding of lithium-ion diffusion behavior (including lateral diffusion) are critical to success.

Balancing Act: Recognizing its potential impact on initial efficiency, energy density, and long-term cycling performance, and effectively managing these factors through size minimization, electrolyte optimization, and charging strategy improvements.

As a professional lithium battery purchaser, gaining a deep understanding of suppliers’ concepts and implementation details in overhang design is an important factor in assessing the true safety performance, long-term reliability, and overall cost-effectiveness of their products. Choosing a battery supplier with a strong design foundation means choosing more reliable safety protection and more lasting battery value.