Research and Application of Lithium Battery Technology in China: Driving the Power of Energy Transformation

Introduction

In the context of global energy transformation, lithium battery technology has become a key support for sustainable development in many fields due to its high energy density, long cycle life and relatively environmentally friendly characteristics. China has made remarkable achievements in the research and application of Li-ion battery technology, not only building a complete and powerful industrial ecosystem in China, but also occupying an important position in the international arena, which profoundly affects the global energy pattern and industrial direction. In this article, we will analyze the research progress of lithium battery technology in China and its wide range of applications.

Research Progress of Lithium Battery Technology in China

Beginning and Early Exploration

China’s lithium battery research began in the 1990s, when lithium battery technology was already in its infancy in the international arena. 1992, the 18th Research Institute of China Electronics Technology Group Corporation (CETC) took the lead in lithium battery research, and in 1994, it successfully launched the first AA-size battery, which utilized its own self-developed synthetic graphite anode, with a capacity of 500mAh, and a specific energy of 500mAh. With a capacity of 500mAh and a specific energy of 94Wh/kg, it took an important step in China’s independent innovation of lithium battery technology. Meanwhile, the Institute of Physics of the Chinese Academy of Sciences and other scientific research institutions are also involved in the project, actively carrying out relevant basic research to lay the theoretical cornerstone for subsequent technological breakthroughs.

Material system innovation and development

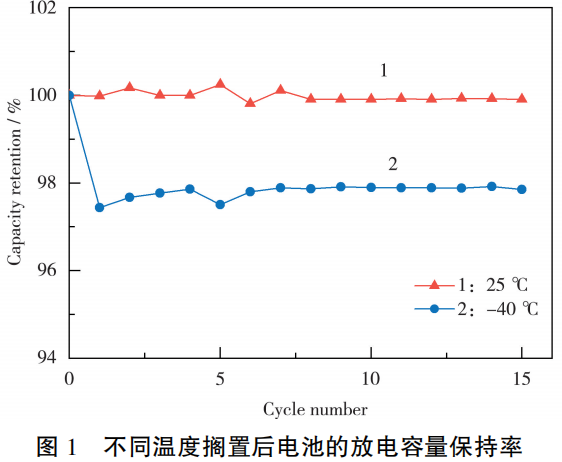

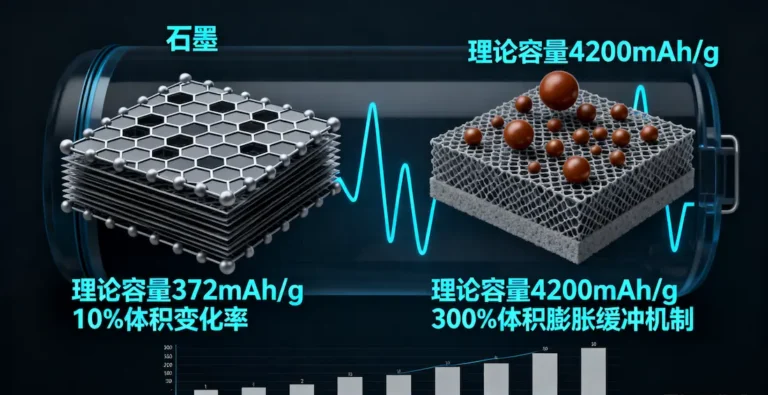

Anode materials: from the initial widely used in consumer electronics products, layered lithium cobalt oxide (LCO), with the evolution of technology, in order to reduce costs and improve safety, layered ternary materials Li (NiCoMn) O₂ (NCM), lithium manganese spinel LiMn₂O₄ as well as polyanionic (NCM), lithium manganate spinel LiMn₂O₄, and polyanionic phosphate materials (e.g., LiFePO₄) have attracted wide attention and achieved industrialization. Among them, LiFePO₄ has become the main cathode material for power and energy storage batteries by virtue of its outstanding advantages such as good safety, long cycle life and low cost. In recent years, high nickel ternary materials (e.g. 811 system) and lithium manganese iron phosphate materials with higher voltage and specific capacity have been developing rapidly, and some enterprises have applied them to their products to optimize battery performance. In addition, anionic active materials such as layered lithium-rich manganese-based materials have also made significant theoretical breakthroughs, with a specific capacity of up to 400mAh/g, pointing out the direction for the development of next-generation high-energy-density batteries. Negative electrode materials: graphite materials occupy a dominant position in the field of lithium battery negative electrode. Early in China, we started from the industrialization of man-made graphite, and the intermediate-phase carbon microsphere (MCMB) materials have been applied due to the characteristics of high vibrational density and low specific surface area, but at a high cost. With the advancement of technology, low-cost natural graphite has become the mainstream of the market after surface modification treatment. To meet the demand for fast charging and low-temperature charging, soft carbon and hard carbon materials are used as part of composite anode for power lithium battery anode. Meanwhile, in pursuit of higher energy density, the development of silicon-based materials (e.g. Si – C, SiO materials) has made significant progress, the Institute of Physics of the Chinese Academy of Sciences (IPS) has a patent for carbon-coated silicon materials, and the 18th Institute of Electric Power of China (IEPC) has put forward the method of stabilization of SiO by high temperature treatment, which has pushed forward the process of the practical application of silicon-based materials. In addition, Li₄Ti₅O₁₂ materials with zero strain are also used in specific areas due to the advantages of fast charging and low temperature charging.

Electrolyte: At the beginning of commercialized lithium batteries, LiPF₆ carbonate mixed solvent electrolyte was used. In order to enhance the performance of electrolyte, in addition to the purification of solvent, the concept of functional electrolyte additives came into being, including SEI film-forming additives (e.g., EC, FEC, etc.), flame-retardant additives, anti-overcharging additives and wetting additives, etc., which have given a strong impetus to the development of high-capacity graphite materials. In order to solve the problem of temperature limitation of polymer electrolytes, such as polyoxyethylene, gel electrolytes have been developed, and the use of lighter plastic shells (such as aluminum-plastic film) has improved the specific energy of the battery mass. In recent years, solid-state electrolyte research and development has become a hot spot, the Chinese Academy of Sciences Institute of Physics and other research teams in the semi-solid-state and all-solid-state battery research and development made a series of breakthroughs, such as the realization of the in situ polymerization of solid-state interfacial fusion, and other key technologies, to significantly improve the battery energy density and safety .

Innovations in Manufacturing Technology

China’s lithium battery manufacturing technology has gradually progressed from early workshop-style production to automation and intelligence. Nowadays, advanced automation equipment and intelligent manufacturing systems are widely used in the production line, realizing precise control and efficient production in the whole process from raw material processing, electrode preparation, cell assembly to battery testing. Intelligent manufacturing not only significantly improves production efficiency and reduces labor costs, but also significantly improves product consistency and quality stability, so that China’s lithium batteries have a strong competitiveness in the global market.

China lithium battery application scope

Power Core: As the power heart of new energy vehicles, lithium battery plays a decisive role in vehicle performance. With the improvement of battery energy density, the range of new energy vehicles has been increasing, and the range of some models has exceeded 700 kilometers or even higher, effectively alleviating consumers’ mileage anxiety. For example, BYD has launched a number of electric vehicles equipped with self-developed lithium iron phosphate “blade batteries”, which ensure high safety while realizing long range and fast-charging performance, and the market has responded enthusiastically. Promoting industrial development: China’s new energy vehicle industry is developing rapidly under the support of lithium battery technology. According to China Association of Automobile Manufacturers (CAAM), in 2024, China’s new energy vehicle production will reach 9.587 million units and sales will reach 9.495 million units, ranking first in the world for many consecutive years. This not only drives the transformation and upgrading of the domestic automobile industry, but also attracts global automobile giants to cooperate with Chinese battery enterprises, such as Volkswagen and Guoxuan Hi-Tech, Tesla and Ningde Times, etc., which promotes technical exchanges and synergistic development of the industry.

Energy Storage

Grid Energy Storage: On the grid side, lithium battery energy storage system is used to reduce peaks and fill in valleys, improve power quality and enhance grid stability. When the grid power consumption is low, the use of low-priced power to lithium battery charging energy storage; power consumption peak, lithium battery release the stored power to ease the pressure of power consumption. For example, in Guangdong, a grid energy storage project, the use of large-scale lithium battery energy storage system, effectively improve the grid peak and valley problems, reduce the cost of grid construction, and improve the operating efficiency of the power system. Distributed energy storage: with solar, wind and other distributed renewable energy supporting, lithium battery energy storage can be unstable renewable energy into stable power output. In some remote areas or islands, distributed photovoltaic combined with lithium battery storage system, to provide local residents with a reliable power supply, to get rid of dependence on the traditional power grid. For example, some islands in the South China Sea, through the construction of solar power stations and lithium battery storage facilities, to achieve energy self-sufficiency, to ensure that the island residents live and produce electricity.

Consumer Electronics

Widely used: Lithium batteries have become the preferred power source for portable consumer electronics such as smartphones, laptops, tablet PCs, digital cameras and so on, thanks to their high energy density, long cycle life and low self-discharge rate. Taking smart phones as an example, with the increase in screen size and functions, the requirements for battery life are constantly improving, and the advancement of lithium battery technology makes the battery capacity of cell phones gradually increase and the charging speed accelerate to meet the needs of consumers for daily use. Promote product innovation: thin and light, miniaturization is the development trend of consumer electronics products, lithium battery technology innovation for product design innovation is possible. For example, the use of soft pack lithium batteries foldable smart phones, under the premise of ensuring the battery capacity, to achieve a thinner and lighter body design, to enhance the aesthetics and portability of the product, for consumers to bring a new experience.

Industrial and Specialty Fields

Power tools: In the field of power tools, lithium batteries replace traditional nickel-cadmium batteries and lead-acid batteries, enabling power tools to have higher power density, longer service life and lighter body. Such as Bosch, Makita and other brands of lithium power tools, widely used in construction, decoration and other industries, improve work efficiency while reducing tool maintenance costs.

Rail transportation: some urban rail transit vehicles use lithium batteries as an auxiliary power supply system or as a power source. The high energy density and fast charging characteristics of lithium batteries can realize rapid charging of trains in a short period of time to meet the needs of frequent start-stop operation and reduce energy consumption and operating costs. For example, in some new tram projects, the use of lithium batteries as a power source has realized zero-emission and low-noise operation of the vehicle, and enhanced the level of green travel in urban public transportation.

Aerospace: Although the aerospace field has extremely stringent requirements for batteries, China’s breakthroughs in the research and development of lithium battery technology have led to its application in some small drones, satellite energy storage and other aspects. In the field of drones, high energy density lithium batteries provide power protection for long endurance and large load drones, which are widely used in surveying and mapping, inspection, logistics and distribution. In the field of satellites, Li-ion batteries are used as energy storage units to provide stable power for satellites when there is insufficient light to ensure the normal operation of satellites.

Conclusion

China has made great achievements in the research and application of lithium battery technology, from material system innovation to manufacturing technology innovation, from new energy vehicles to energy storage, consumer electronics and industrial applications, forming a complete and dynamic industrial ecology. In the future, as R&D investment continues to increase and technological innovation continues to deepen, China’s lithium battery technology is expected to make greater breakthroughs in higher energy density, longer cycle life, higher safety and lower cost, further expanding the boundaries of application, playing a more critical leading role in the process of global energy transformation and industrial upgrading, and contributing to the building of a sustainable energy future.