China’s new energy vehicle battery technology revolution

All-solid-state batteries are still stable after shearing, lithium iron phosphate batteries are ten years free of replacement, sodium ion batteries conquer -40℃ extreme cold environment – China is reconstructing the global new energy vehicle battery rules with a triple technology route.

1, technology leap: three routes to reconstruct the competitive landscape

All-solid-state battery: zero breakthrough in commercialization

In June 2025, Pure Lithium New Energy was the first in the world to achieve zero breakthrough in the commercialization of all-solid-state batteries. Its products adopt organic and inorganic fusion solid-state electrolyte, completely eliminating liquid electrolyte and diaphragm, and have passed extreme safety tests such as steel needle penetration, metal shear and violent puncture. When the battery pack is cut from it, not a single drop of electrolyte seeps out from the inside, and the cut battery still continues to provide stable power supply for electric lights.

This breakthrough was made possible by the fact that China was the first country in the world to establish a judgment standard for all-solid-state batteries.2025 The “Judgment Method for All-Solid-State Batteries” (T/CSAE 434-2025), released in May 2025, establishes a “two-step” certification system: qualitative testing requires that there is no liquid seeping out of the breach; quantitative testing requires that the weight loss rate is <1% after drying in a vacuum at 120°C for 6 hours; and quantitative testing requires that the weight loss rate is <1% after drying for 6 hours. After 6 hours of vacuum drying at 120℃, the weight loss rate is less than 1%. The measured quality loss rate of pure lithium new energy products is only 0.023%, far exceeding the standard requirements.

The industrialization process has been fully accelerated: China Electric Vehicle Association (C EVAA) predicts that all-solid-state batteries will be installed in vehicles in 2027, and enter the GWh-level mass production stage in 2030. BYD plans to demonstrate vehicle installation in 2027, and Ningde Times focuses on the development of solid-state batteries for eVTOL vehicles.

Lithium iron phosphate batteries: a comeback in the high-end market

BYD has pushed lithium iron phosphate batteries into the luxury car segment with its blade battery structure innovation:

Energy density leap: second-generation blade battery cell energy density reaches 250Wh/kg, pack energy density breaks through 200Wh/kg

Low-temperature performance breakthrough: single-crystallization technology makes the capacity retention rate of -20℃ up to 90%

Ultra-fast charging technology: Nindege’s Shenxiang battery realizes a 10-minute charging to increase the range by 400km.

Market share confirms the technological advantage- -2025 Q1, lithium iron phosphate batteries in new energy vehicles installed volume accounted for 41%, compared with 2024 to improve 16 percentage points.

Sodium-ion battery: a strategic path to resource autonomy

Facing lithium resource constraints (China’s reserves account for only 16.5% of the world), Ningde Times launches second-generation sodium-ion batteries in 2025:

Extreme environmental adaptability: maintain normal discharge performance in -40℃ low-temperature environment

System integration innovation: through lithium-sodium AB battery mix-and-match technology, sodium batteries are arranged in the low-temperature area of the battery pack, and the low-temperature range is improved by 5%

Cost advantage: KODAK Pilot confirms that the system cost of sodium batteries is more than 30% lower than that of lithium batteries

Acceleration of industrialization: China’s sodium-ion power batteries installed capacity in Jan-Sep, 2024 Over 3.7MWh, Chery QQ ice cream model supported by Ningde Times is the first to land.

2. Materials Revolution: The Innovation Chain from the Lab to the Mass Production Line

Solid-state electrolyte breakthroughs

Sulfide system has become the mainstream technology route:

Guoxuan Hi-Tech developed automotive-grade sulfide all-solid-state battery “Jinshi Battery”, which passed 200℃ hot box test

The ionic conductivity of sulfide electrolyte of Fu Energy Technology reached 1.2mS/cm, surpassing the international level at the same time.

Halide integrated cathode opens the era of electrode self-repair: Academician Sun Xueliang’s team developed iron-based halide material, which integrates cathode active material, electrolyte and conductive agent into a single material:

Energy density reaches 725.6 Wh/kg

Capacity retention rate of 90% for 3,000 cycles at 5C multiplication rate

Brittle-tough transition during charging and discharging, automatic repair of electrode cracks

Breakthrough in localization of manufacturing process

In June 2025, China’s first high-power, large-amplitude magnetron sputtering equipment passed the acceptance test, solving the “neck” problem of composite collector production:

Copper foil winding speed increased by 10 times.

Coating thickness>1μm, one production cycle up to 20 hours.

Breaking the monopoly of Japanese equipments, reducing the production cost of solid-state battery by 30%.

Synchronization of dry electrode process: Pilot Intelligence customized solid-state dry electrode coating equipments for South Korea’s battery enterprises to achieve exports, solving the interface impedance problem caused by the solvent residue of the wet process.

3. Application Scenario: Boundary Breaking from Passenger Cars to Low Altitude Economy

Reconstruction of Safety Standards for Electric Vehicles

The CTP 2.0 battery pack put into production by Ningde Times at the Askworld Super Factory sets a new benchmark for ten-layer thermal safety protection:

Five-layer safety cladding design for battery cells

AI prediction of hidden dangers by vehicle cloud cooperative monitoring system

Full high-voltage thermal runaway non-spreading technology platform

Biyadi blade battery, on the other hand, realizes 3,000 cycle life through honeycomb aluminum plate structure and ceramic-coated diaphragm, which supports the whole vehicle lifecycle without replacement.

Low Altitude Economic Power Engine

The eVTOL vehicle imposes stringent requirements on battery performance:

Energy density >300Wh/kg: Voron Technology’s second generation semi-solid state battery has an energy density of over 330Wh/kg, and has been designated by eVTOL customers in the United States.

High-rate charging and discharging: Xinjie Energy’s “Falcon” lithium-metal solid-state battery supports 4C charging and discharging and realizes 48-minute endurance with eVTOL.

The Civil Aviation Administration of China (CAAC) predicts that the market size of low-altitude economy will reach 1.5 trillion yuan in 2025, and solid-state batteries will become the core support.

City-level security infrastructure

Pure lithium new energy to build “car – electricity – cabinet – cloud” four-dimensional system, landing in Beijing Yizhuang super instant delivery scene:

The recycling and reuse rate of all-solid-state battery switching cabinet is over 90%

Stable operation in 85℃ high temperature environment

Cracking the problem of lithium battery fire in electric bicycle (91.7% of accidents in 2024 are triggered by thermal runaway of lithium battery)

4. Industrial Chain Competition: Global Strategy of Chinese Enterprises

Export of Technology Standards

China-led power exchange standard (GB/T 40032-2021) has become a proposal of the International Electrotechnical Commission (IEC); all-solid-state battery judgment standard has attracted the attention of Japanese and Korean enterprises, and may become a blueprint for international standards.

Globalization of production capacity

| corporations | Globalization strategy | Technology export model |

|---|---|---|

| Ningde Times | Hungary builds Europe’s largest battery plant | Ford Michigan Plant Technology Licensing |

| BYD Company (company name) | Thailand plant goes into operation, targeting Southeast Asian market | Blade Cell International Patent License |

| China Airlines | Volkswagen Group in Portugal | High-nickel ternary battery technology cooperation |

Closed-loop resource construction

Breakthrough in lithium recycling technology: GLM has built the world’s first closed-loop base of “battery recycling – material recycling – battery remanufacturing”, with a nickel-cobalt-manganese recycling rate of more than 95%.

Sodium resource development: Meilian New Material has completed the mass production of Prussian Blue anode materials, building a sodium electric whole industry chain.

5. Challenges and Prospects: Triple Tackle of Industrialization

All-solid-state battery mass production bottleneck

Despite the commercialization breakthrough, solid-solid interface impedance is still the core obstacle:

The interface impedance of current mass-produced products reaches 80-100Ω-cm².

Jusen-Acco has constructed LLZO buffer layer through atomic layer deposition (ALD) technology, which reduces the impedance to below 40Ω-cm².

Cost and Resource Challenges

Mass production cost: semi-solid-state battery has been reduced to 1 yuan / Wh, full-solid-state battery due to vacuum vapor deposition process cost up to 3.5 yuan / Wh

Lithium resource constraints: Chinese enterprises through the Indonesian nickel mine, the Argentinean salt lake lithium project to reduce the degree of dependence on foreign countries, the cost of lithium extraction from the salt lake is 30% lower than the cost of Australia’s hard rock mines

International policy barriers

EU Carbon Border Tax (CBAM): 17%-35.3% tariffs on Chinese electric vehicles from October 2024

U.S. IRA bill: requires local sourcing of key battery minerals to reach 80% by 20255

When the EU is still arguing over battery safety standards, China has made all-solid-state batteries stable power supply after shear; when Japan is sticking to the hydrogen energy route, China’s sodium batteries have already lit up the lighthouse in the extreme cold of -40℃.

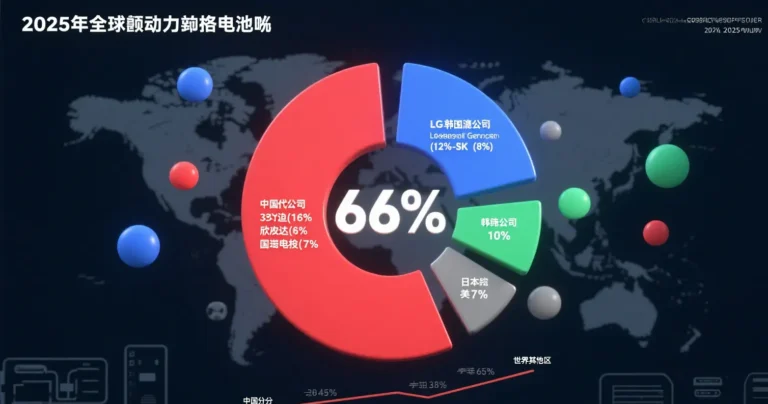

The global power battery landscape is being reshaped by Chinese technology: Ningde Times has been the world’s No. 1 in installed capacity for eight consecutive years, with a market share of 47.08% in 2024; Chinese power battery patents account for 47% of the world’s patents, and the number of patents in the field of solid-state batteries is three times that of Japan.

According to EVTank’s forecast, the global shipment of solid-state batteries will reach 614.1GWh in 2030, and the penetration rate of sodium batteries in the field of energy storage will exceed 30%. This energy revolution defined by China is proving that safety and performance are never a single choice, resource constraints are not the end game, and technological innovation is the eternal solution.