China’s UAV Battery Technology Revolution: Solid State Breakthroughs and Extreme Cold Challenges

From the 320Wh/kg solid-state battery mass-produced at the Hunan production base to the wide-temperature-range power supply for stable flights in the -36°C extreme cold environment of Mohe, China is reshaping the global UAV power landscape with technological innovation.

01, the technological watershed behind the industrial explosion

The year 2025 has become a strategic turning point for China’s UAV battery industry. With the explosive growth of low-altitude economy worldwide, industrial-grade drones have put forward unprecedentedly stringent requirements for power systems – energy density needs to exceed 300Wh/kg, safety needs to withstand extreme working conditions, and charging and discharging efficiency determines the life and death of endurance.

Traditional lithium-ion batteries have encountered bottlenecks in energy density and temperature adaptability, forcing Chinese enterprises to accelerate technology iteration. Hunan Jusenan High-Tech Co., Ltd. took the lead in realizing the mass production of solid-state batteries for drones, and the energy density of its products reaches 320Wh/kg, which is 80% higher than that of traditional batteries.

The Dalian Institute of Chemical Physics of the Chinese Academy of Sciences has even developed a 400Wh/kg ultra-high energy density battery, which will increase the endurance of drones by 20%-40%. This revolution driven by solid-state electrolyte and wide temperature range technology is making China stand on the high point of the global UAV power battery.

02, solid-state batteries: energy density of the road to leapfrog

Mass production breakthrough and performance benchmarking

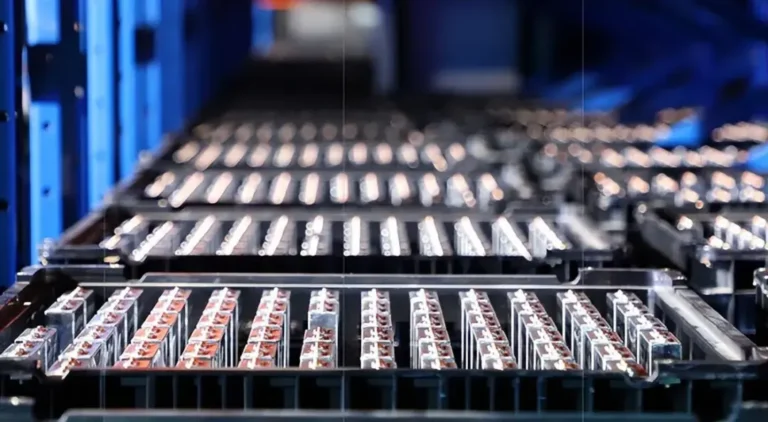

The 1.5GWh fully automated production line established by Hunan Jusenan High-Tech is mass-producing 320Wh/kg solid-state batteries with a 96% pass rate. Its core lies in adopting high-entropy solid-state electrolyte system and solving the impedance problem of solid-solid interface through nano-scale interface modification technology. “This technology has epoch-making significance for the development of industrial chain”, said Tang Xinping, Chairman of the company.

In June 2025, Hoyuan Li-Tron announced the delivery of the first batch of special UAV solid-state batteries with energy density of 320-600Wh/kg, supporting 20-100Ah customized capacity. Its technology highlights are:

In-situ curing process: forming a 3D network solid-state electrolyte layer between the electrodes

Interface modulation technology: lowering the interface impedance to below 15Ω-cm²

12 extreme safety tests: including harsh conditions such as pinprick and extrusion

Disruptive innovation of material system

The solid-state battery precursor material developed by Sankin Lithium under Lonpac Technology, through the design of high nickel ternary structure (LiNi₀. ₈Mn₀. ₁Co₀. ₁O₂) realizes a jump in energy density of more than 20%. The material maintains more than 80% capacity at -30℃, overcoming the problem of performance degradation in high-altitude and low-temperature environments.

The next-generation products of Heyuan Li-Tron will adopt sulfide composite electrolyte, and the mass-produced batteries are expected to break through 400Wh/kg energy density in the second half of 2025, which is directly aimed at the power demand of eVTOL aircraft.

03、 Wide Temperature Range Technology: Conquering Extreme Environments

A Chinese Solution for Extreme Cold Environments

In March 2025, Academician Chen Zhongwei’s team from the Dalian Institute of Chemical Physics, Chinese Academy of Sciences, delivered a shocking answer – the six-rotor UAV equipped with ultra-low-temperature and high-energy lithium batteries completed a test flight in the -36℃ environment of Mohe, with smooth voltage output and no power fluctuations.

The core technology breakthroughs include:

Ultra-low temperature electrolyte formulation: adopting a solvent mixture of fluorinated ethylene carbonate (FEC) and methyl decanoate, with the freezing point reduced to -75℃

Silicon-carbon composite anode modification: constructing an elastic buffer layer on the surface of the silicon particles to inhibit low-temperature expansion

Adaptive thermal management system: with a self-heating rate of up to 5℃/minute during low-temperature startup

Engineering breakthroughs in wide-temperature performance

The battery module has an energy density of 340Wh/kg and operates stably in a temperature range of -40℃ to 60℃. Its low-temperature range degradation rate is controlled at less than 10% of the normal temperature state, which is far lower than the industry’s degradation level of 30%-50%.

The key innovations are:

Composite diaphragm technology: ceramic-coated diaphragm with both high-temperature and low-temperature resistance

Multi-layer composite structure design: optimized thermal management and encapsulation process

Low-temperature impedance optimization: lithium-ion solvation structure regulation to improve ionic conductivity

04. Boundary breakthrough in application scenarios

Special operation scenarios

The special UAV batteries delivered by HYLT have been used in border patrol, disaster relief and other scenarios, and their 20C high rate discharge capacity supports emergency climbing and high-speed maneuvering of UAVs. In the actual test, the overall temperature rise of the battery under high rate discharge condition is less than 15℃, which greatly improves flight safety7.

Polar scientific research and logistics transportation

Dalian Institute of Chemical Industry’s wide temperature range battery enables UAVs to achieve a single range of more than 200 kilometers in polar scientific research, solving the problem of frequent return flights caused by the shrinking range of traditional batteries in low-temperature environments.2025 The test flight of the industrial-grade composite-winged UAV has completed a 3-hour continuous flight mission, paving the way for long-distance logistics transportation.

Construction and Robotics Synergy

Solid-state battery technology is being extended to emerging fields – The 350Wh/kg solid-state battery packs for construction robots from Hoyuan Li-Tron have resulted in a 40% weight reduction for the equipment and have passed safety tests such as pinprick and extrusion. This signifies that drone battery technology is reshaping the intelligent equipment ecology.

05, the industry chain competition new pattern

Scientific research institutions lead original innovation

Dalian Institute of Chemical Physics: Academician Chen Zhongwei’s team owns 23 core patents in the field of wide-temperature domain electrolyte

Shenyang Institute of Automation: industrial-grade drone platform design and battery system integration technology

Industry-academia-research synergism: Jusen-Ankor and Central South University jointly develop high-entropy electrolyte materials

Differentiated Layout of Enterprise Echelons

Technology Route of Leading Enterprises

| company identification | Technical characteristics | Areas of application | mass production schedule |

|---|---|---|---|

| Hisamaka (name) | 320Wh/kg high entropy solid electrolyte | Consumer-grade drones | 1.5GWh has been put into production |

| Liyuan Lithium Corporation (PRC state owned lithium company) | 600Wh/kg sulfide electrolyte | Specialty drones | GWh line under construction |

| Sankin Lithium | Low-temperature precursor materials | eVTOL flying machine | Accreditation stage |

Jusen Anglo plans to realize mass production of solid-state batteries for two-wheeled vehicles and energy storage in 20259; Heyuan Li-Tron accelerates the construction of 10GWh production capacity by relying on the background of state-owned capital (invested by Huai’an Financial Development Group);7; SANKYN Li-ion has been authorized by the Suzhou government as the “Low Altitude Economy Technology Innovation Center”, and has become a key node of the regional industrial chain.

06, the future challenges and technology attack direction

Solid-state battery mass production bottleneck

Despite the continuous breakthroughs in laboratory technology, solid-solid interface impedance is still the core obstacle to large-scale production. The interfacial impedance of current mass-produced products reaches 80-100Ω-cm², resulting in lower charge/discharge efficiency. By constructing a lithium lanthanum zirconium oxide (LLZO) buffer layer on the cathode surface through atomic layer deposition, Jusen-Acco has been able to reduce the impedance to less than 40Ω-cm².

Cost and Resource Challenges

The cost of semi-solid-state batteries has dropped to $1/Wh, but full-solid-state batteries still cost as much as $3.5/Wh due to precious-metal doping (e.g., germanium, gallium) and vacuum vapor deposition processes.6 Hopen Lithium Creation is developing a sulfur-silver-germanium-mineral-type electrolyte with no rare metals, with the goal of compression of the cost to less than $2/Wh7.

Lack of standard system

UAV battery has not yet formed a unified safety test standard. The 12 extreme tests proposed by Heyuan Li-Tron (including the pin prick test after freezing at -40°C) may become an industry reference7, but the airworthiness certification system still needs to be improved.

07 、The Power Engine of Low Altitude Economy

The global UAV battery market will maintain a CAGR of 35% from 2025-2030. With the dual breakthroughs of solid-state batteries and wide temperature range technology, China has taken the high ground in energy density and low-temperature performance.

When the production line of Jusen Angao is running around the clock, and when the batteries of Dalian Institute of Chemical Physics are stabilizing their output in the frigid air of Mohe, the UAV power system made in China is redefining the boundaries of low-altitude economy.

From consumer drones to polar research equipment, from logistics networks to smart construction sites, this revolution driven by China’s solid-state battery technology is not only changing the way energy is stored, but also reshaping the way humans utilize the sky.

In the next five years, with the mass production of 600Wh/kg batteries and -50℃ ultra-low-temperature batteries, China’s drone batteries will help mankind enter the real “all-area flight era”.

Solid-state batteries have a wide range of future applications