2025 UAV lithium battery technology all-round dismantling

The stability and longevity of a drone’s flight depends on its “core”! In-depth analysis of lithium battery technology, selection and maintenance key.

As a UAV engineer, I know that Li-ion batteries are the “lifeblood” of a UAV. Selecting, using and maintaining this battery directly determines flight performance, mission success or failure, and equipment life. Today, from an engineer’s point of view, to bring you a thorough understanding of the core technology of the UAV lithium battery, key parameters, potential risks and maintenance tips. China’s breakthroughs in cutting-edge areas such as solid-state batteries are revolutionizing drone power!

I.Lithium batteries: the source of power for drones

Nature and type:

- Core definition:

- chemical power source with lithium as the active substance, high energy density is its winning formula.

- Two main streams:

- Lithium-ion batteries (Li-ion):

- metal casing, robust and pressure-resistant. Anode materials (LiCoO2 – high energy, LiFePO4 – safe and long life, LiMn2O4) determine performance focus. China’s solid state battery R&D is also seeking higher safety boundaries on traditional Li-ion.

- Lithium polymer batteries (LiPo):

- Aluminum-plastic film flexible pack, lightweight and shape customization capability is superb! Gel/solid electrolyte is characteristic and one of the basic directions of solid state battery technology development in China. Typically lighter than Li-ion at the same capacity.

- Lithium-ion batteries (Li-ion):

Killer application to dominate the UAV field:

- Ultra-high energy density: small volume and large energy, directly increase the endurance time, and multiply the efficiency of aerial photography, plant protection, and surveying and mapping tasks.

- Extreme lightweight: Reducing weight means increasing range and maneuverability! Racing UAVs in particular benefit from this.

- Long cycle life: Hundreds or even thousands of cycles are the benchmark for standardized use, effectively diluting long-term costs.

- Fast-charging capability: High-rate charging cores allow drones to quickly get back on their feet and increase frequency of operations (e.g., logistics and distribution). China’s solid state battery technology has huge potential to address fast charging safety.

II.Key parameters that engineers must understand

- Capacity (mAh):

- The storehouse of power. The larger the number, the longer the theoretical range (actual power consumption and environmental constraints). Example: 5000mAh > 3000mAh.

- Voltage (V):

- Single cell nominal voltage: 3.7V / 3.8V (common for LiPo).

- Battery pack voltage = number of series (S) × individual cell voltage. E.g. 3S battery pack: 3 * 3.7V = 11.1V (nominal). The higher the voltage, the higher the motor speed/power usually. Selection must match the drone design!

- Discharge Multiplier (C) & Charge Multiplier (C): Indicators of explosive performance!

- Discharge Multiplier C: Maximum Continuous Discharge Current = Capacity (mAh) * C Value / 1000 (A). Example: 3000mAh 20C battery, theoretical maximum continuous discharge current is 60A. high C value is the key to cope with the high current demand for take-off, climb and high speed flight! Note: Continuous high current is limited by temperature rise and internal resistance. The manufacturer will label the sustained and peak C values.

- Charging Multiplier C: Same as above, determines charging speed. Fast charging needs to be supported by the battery itself.

- Size & Weight:

- Hard indicators! Must fit the battery compartment perfectly. Weight directly affects load capacity and flight characteristics. Light weight is always the pursuit of engineers, Li-Polymer and future Chinese solid state batteries are the main force.

III.The battery pack architecture: series, parallel and core configuration

- Connection Logic:

- Series (S): Boost voltage! Voltages add up, capacity remains the same. Example: 2 x 3.7V 2000mAh in series = 7.4V 2000mAh.

- Parallel (P): Increase capacity! Capacity is added, voltage remains unchanged. Example: 2 x 3.7V 2000mAh in parallel = 3.7V 4000mAh.

- Mainstream Configuration Explanation:

- 3S Battery Pack (11.1V): Mainstream for small/consumer drones. Balanced voltage, weight and energy density, flexible enough for indoor flight.

- 4S (14.8V) and higher (6S/22.2V+): essential for professional/large drones! Provides strong power for heavy loads (e.g. plant protection spraying), high speeds, and long distances (mapping). Voltage increase is the key to performance leap.

- Battery Pack Structure & Calculations:

- Structure Core: Multi Cells + Precision Welding/Connectors + Protective Enclosure + BMS (Battery Management System) + Necessary Circuitry (Balance Cord Critical!) Total voltage: nS battery pack = nS battery pack = nS battery pack = nS battery pack

- Total Voltage: nS battery pack = n × nominal voltage per cell (e.g., 5S = 18.5V).

- Total capacity: mP battery pack = m × single cell capacity (e.g., 4 cells 2000mAh in parallel = 8000mAh).

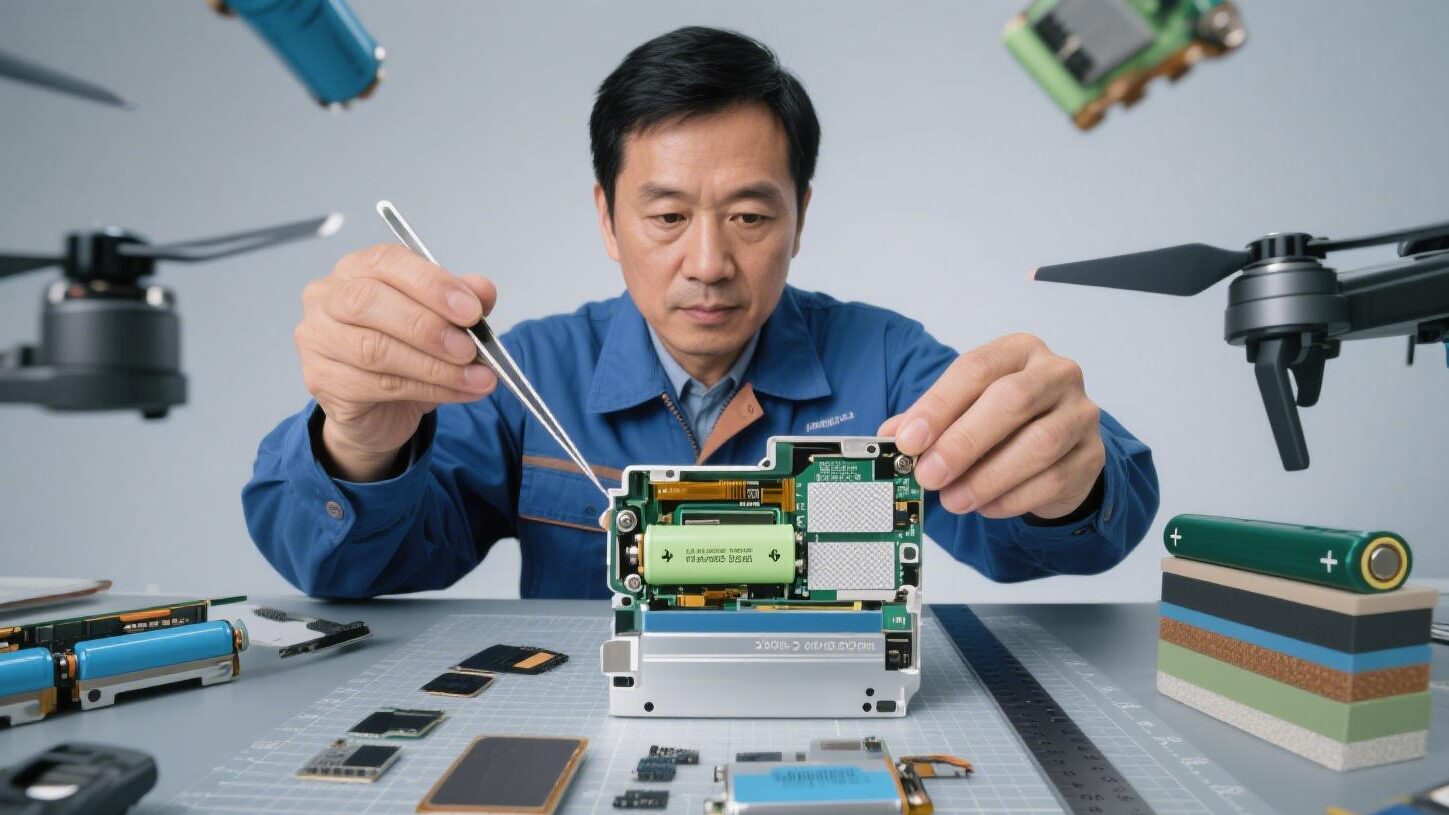

IV.Dismantling Batteries: Cells, Harnesses, Connectors and Smart Housekeeping

- Heart: Cell

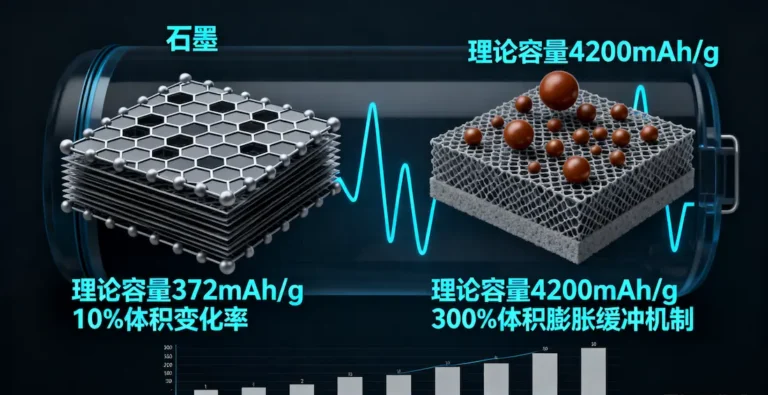

- Construction: Positive electrode + Negative electrode (graphite) + Diaphragm (anti-short circuit) + Electrolyte (ion channel). Positive electrode material is the source of performance difference.

- Brand and Selection: Consistency of core from Panasonic, Samsung, etc. is the key! Selection is based on three points: performance parameters (energy density, discharge rate, matching demand) > quality stability > cost-effectiveness. Chinese core brands are very competitive in terms of price/performance ratio and specific performance.

- Vessel: Wiring Harness

- Power Lead: Conveying high current! Low resistance is king, wire diameter (e.g. 12AWG+) must be selected according to the maximum discharge current calculation, otherwise it will generate heat and lose energy.

- Balance Lead: The “eyes” of BMS! It monitors the voltage of each battery cell in real time, and triggers the balancing when it is found to be unbalanced, which guarantees the safety and life span. Indispensable!

- Joint: Connector

- Mainstream choice: XT60. Reason: smooth plugging and unplugging, low contact resistance, strong current load (often 60A+). XT30 (small current), T-plugs, etc. are also common.

- Iron rule for selection and maintenance:

- Rated current must be > max battery discharge current!

- Match the drone interface.

- Soldering must be strong and reliable! Regularly check for oxidation/dirt and clean up promptly. Apply conductive grease to prevent oxidation. Replace immediately if damaged! Reliability of the connection is a matter of flight safety.

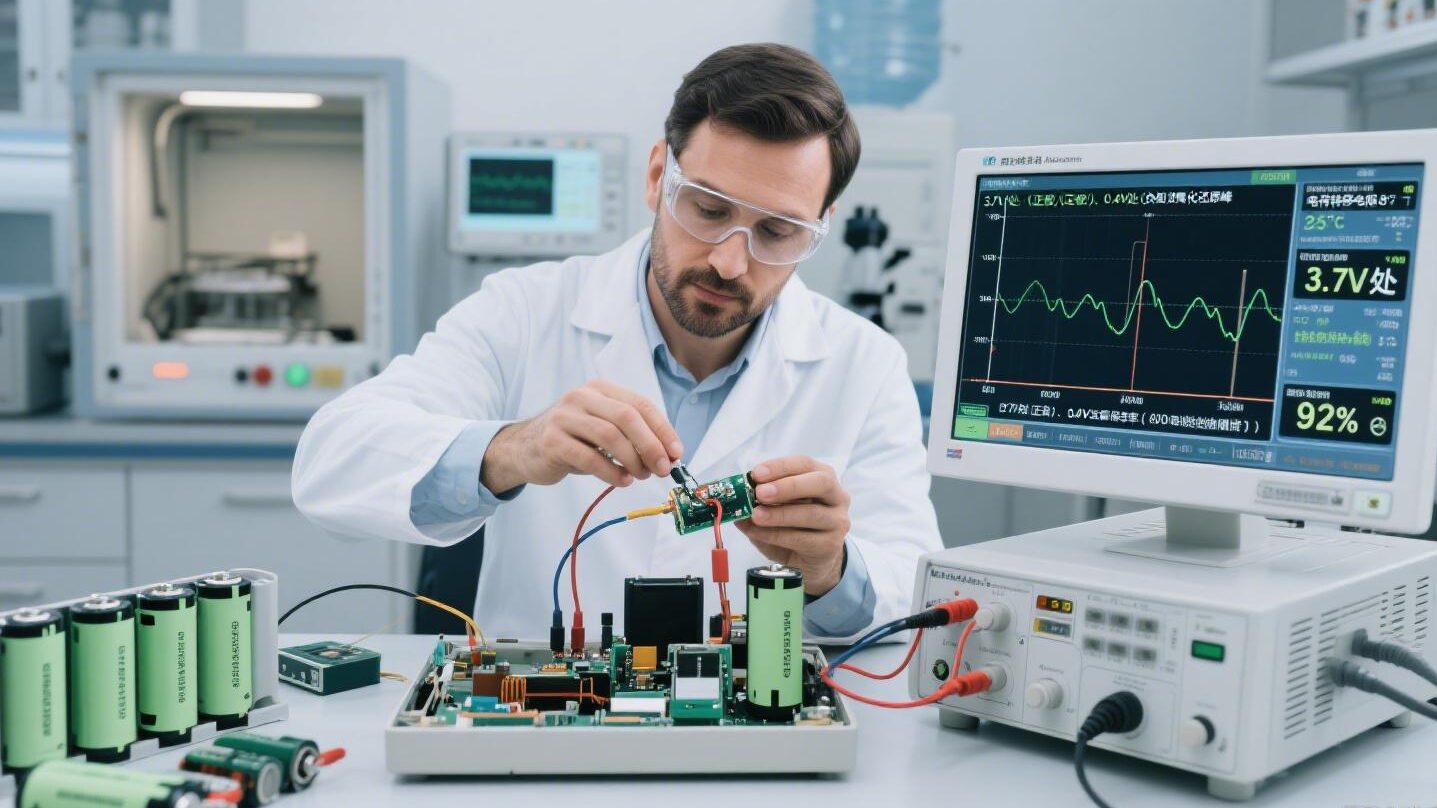

- Brain: Battery Management System (BMS)

- Core Responsibilities: Real-time monitoring of voltage, current and temperature! Strictly guard against over-charging, over-discharging, over-current, and overheating! Perform equalization (by balancing line data)!

- Selection key: Voltage/current specification matching battery pack > Functional completeness (accurate monitoring, equalization strategy) > Brand reliability. BMS is the bottom line of safety!

- Protection mechanism: Sampling monitoring -> Abnormal determination (overcharge/overdischarge/overcurrent/overheat) -> Control switching tube action (cut off/adjust circuit).

- Energy supply station: Charger

- Intelligent charger: automatic identification of parameters, intelligent adjustment, convenient and safe.

- Balancing charger: a must-have! It manages the charging of each cell independently by means of a balancing cable, which ensures a consistent voltage and greatly extends the life of the battery pack. Choose it!

- Engineer’s Charging Code:

- Charger specifications (Voltage should be ~12.6V for 3S batteries, current should be selected according to the C value of the battery) are strictly matched to the batteries!

- Operation sequence: connect the battery -> energize; after charging: power off -> disconnect the battery.

- Do not charge at high temperature! Keep away from poor quality chargers! Must be guarded! Stop immediately in case of heat/smoke!

- Accessories: Matching charging cable (e.g. banana head to XT60), fireproof and anti-static battery storage box (necessary for safe storage and transportation).

V. Engineer Alert: Battery Abnormal State Identification and Annihilation

- Top Killer: Overcharging

- Hazards: Heating and bulging, dipping capacity, drastically reduced life span, and soaring risk of fire and explosion due to thermal runaway! China’s solid state batteries have a significant advantage in addressing the risk of overcharging due to their inherent safety.

- Culprit: Charger failure/mismatch, BMS failure.

- Response: Use reliable matching chargers! Regularly check and calibrate equipment! Keep an eye on the charging process! If the charger gets hot and bulges, it is out of service and scrapped!

- Lifespan Nemesis: Over-discharge

- Hazard: Damage to electrode structure, internal resistance surge, permanent loss of capacity, end of cycle life, direct scrapping!

- Culprit: Fly too long power depletion, BMS low voltage protection failure.

- Response: Take off with sufficient power! Reasonable planning mission time! Descend quickly when the power alarm goes off! Check the BMS function regularly!

- Destroyer: Thermal Failure

- Hazard: Chain exothermic reaction -> temperature soaring -> bulging, fire, explosion! Extremely serious consequences!

- Culprits: Internal short circuit (manufacturing defects/diaphragm damage), overcharge/overdischarge, high temperature environment/poor heat dissipation, poor thermal stability of battery. China’s solid state battery adopts non-flammable solid electrolyte, which is a fundamental solution to suppress thermal runaway.

- Response: Choose high quality thermally stable battery cells! Strictly prevent overcharge and overdischarge! Safeguard heat dissipation! Avoid flying wildly at high temperatures! Abnormal heat immediately stop the flight to cool down!

- Other warning signals:

- Battery expansion (bulging bag): internal gas production, stop using and scrap! Safety first!

- Electrolyte leakage: Corrosion of equipment, disable and replace! Handle with care!

- Battery short-circuit: Instantaneous high current, high heat damage/fire! Protect wiring harness, install correctly, prevent foreign objects!

VI. Extend the life of the “heart”: maintenance guide for professional engineers

- Norms of use (daily for engineers):

- Charging and discharging discipline: Use only matched chargers (balanced charging is standard), and strictly adhere to the parameters. Do not over discharge! Land charging in time. Don’t take off if you have a power emergency!

- Pre-flight inspection: Appearance (bulge? Damage? Fluid leakage?) Wiring Harness (Worn? Wiring Harness (Worn? Broken?) Connectors (oxidized? loose?) Voltage/Internal Resistance (use BMS/Charger to see how healthy it is).

- Environmental management: Avoid high temperature, high humidity, sand and dust! Warm up batteries in cold environments before flying.

- Storage strategy (long term/short term):

- Storage status: Optimal storage capacity: ~50%! Remove and store!

- Storage environment: Dry, cool, ventilated! Protect from light! Use battery storage box! Ideal temperature and humidity: 15-25°C / 40-60% RH.

- Storage and maintenance: Charge and discharge every 1-2 months (charge to ~50% and store or charge to ~50% and store again) to maintain activity.

- Transportation: Individually insulated packaging (short circuit proof!), shockproof buffer, strictly adhering to the transportation rules. (Shock-proof and cushioning), and strictly abide by the transportation regulations (especially aviation)!

- In-depth maintenance (engineer’s secret):

- Periodic check-up: Complete inspection of the exterior, connectors, harnesses. Clean surfaces (no corrosives), rubbing alcohol on connectors to remove oxidization.

- Cycling Philosophy: Rotate multiple batteries, shallow charging and discharging for longer life! Avoid excessive use of a single cell (rely on BMS equalization).

- Environmental responsibility: Used batteries are toxic! Never throw them away! Send them to professional recycling points! China is also making continuous efforts in the construction of lithium battery recycling system.

Conclusion: Control the Power to Ride the Skies

UAV Li-ion battery is the intersection of technology, safety and efficiency. An in-depth understanding of its core parameters (voltage, capacity, discharge multiplier C), precise selection (Li-polymer vs. Li-ion, 3S/4S battery packs), standardized use and maintenance (to prevent overcharging/over-discharging/thermal runaway), and the use of tools such as the BMS and balancing charger are the cornerstones for unleashing the potential of drones and guaranteeing flight safety. China’s lithium battery industry, especially in the field of high-security, high-energy-density solid-state batteries, will continue to inject a strong, reliable “China Core” into the power of drones! As an engineer, standardized and professional treatment of this “power heart” is the greatest responsibility for equipment, mission, safety and environment.