2025 Lithium Battery Charging Methods Guide

“When Tesla boosted 21700 battery cycle life to 2,000 cycles with pulse charging, and a power tool brand recalled 120,000 sets of products due to uncontrolled constant voltage charging – charging algorithms are becoming the second lifeline for batteries. As an engineer involved in the development of the IEC 62133 standard, I will use blood and tears cases to dismantle the life and death boundaries of lithium battery charging methods in 2025.”

I.constant current charging (CC): simple and brutal “double-edged sword”

Mechanism of operation: current constant as a horizontal line (e.g., 1C = 3A), voltage continues to climb

Deadly traps:

▶ Overvoltage breakdown: when the voltage exceeds 4.25V, the risk of lithium precipitation of the positive electrode ↑ 300% (confirmed by the laboratory TEM microscope)

▶ Thermal runaway fuse: > 1C charging rate of temperature rise of up to 0.8 ℃ / min

Golden Rule: only recommended for lithium iron phosphate (LFP) or SOC <20% of the emergency! Replenishment

engineers warn: “constant current charging of ternary batteries must be equipped with a voltage threshold emergency stop, otherwise it is a mobile bomb!

II. constant voltage charging (CV): slow poison

Operation mechanism: voltage locking (e.g. 4.2V), exponential decay of current

Three major sins:

Chronic suicide by lithium analysis: lithium dendrite growth due to initial high-current > 2C (22% capacity degradation after cycling for 50 times)

Black hole in time: charging to 95% of the power consumption accounted for 70% of the whole process

Exacerbation of polarization effect: ion buildup leads to rising internal resistance and ↑ 15% ohmic heat loss

The only applicable scenario: lithium titanate (LTO) batteries ( Only applicable scenario: lithium titanate (LTO) battery (2.4V cut-off voltage without lithium precipitation risk)

III.Constant current – constant voltage charging (CCCV): the secret of the industry’s gold standard

Two-stage subtle control

| point | Current/Voltage | goal | boundary point |

|---|---|---|---|

| CC segment | Constant current 0.5-1C | Quickly recharges to 70% capacity | Voltage up to 4.2V (ternary) |

| CV segment | Voltage constant 4.2V | Trickle fill remaining 30% | Current ≤0.02C |

Parameter optimization military regulations

Ternary batteries: 4.2V cut-off voltage + 0.02C withdrawal current → cycle life 800 cycles +

Li-FePO4: 3.65V cut-off voltage + 0.05C withdrawal current → avoiding the trap of the “false voltage”

Fatal detail: CV section timeout of 30 minutes without reaching 0.02C? –Battery is old!

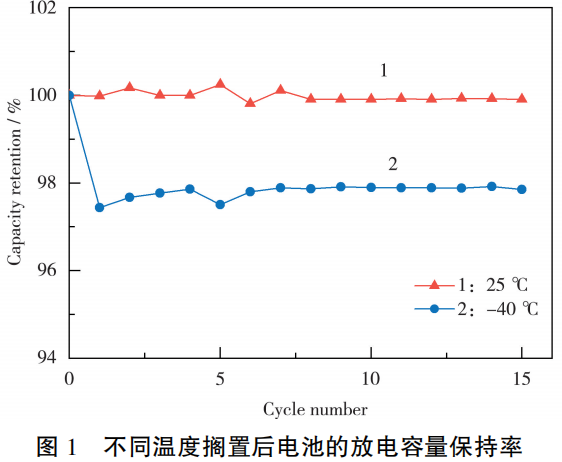

IV.Pulse charging: the balancing act of range and life expectancy

Revolutionary protocol:

[0.2C constant current charging 30s → stop charging 10s → 0.5C pulse charging 5s] cycle to 4.2V

Four major advantages:

Polarization Effect Zeroing: Ion diffusion restores the concentration gradient during the stopping period

Temperature Rise Suppression: ↓8℃ compared to the peak temperature of CCCV mode

Lithium Analysis Suppression: Pulse gap allows lithium ions to be embedded in an orderly manner

Activation of Dormant Cells: Repair of the capacity degradation due to sulfation.

Application Prohibition:

▶ >2C pulses damage graphite anode structure

▶ Low-end BMS cannot support millisecond-level control.

Tears of blood case library

Drone bombing: a manufacturer’s CC charging did not set a 4.2V cutoff → battery cell expansion broke through the shell

Energy storage plant fire: CV charging early current out of control → module temperature difference >15℃ triggered the heat spread

Power tool revolution: Bosch uses pulse charging to boost battery pack cycle life to 1,500 times

Purchasing Guide

Signing the contract must check the BMS charging logic (require algorithm flow charts)

Verify the manufacturer’s 0.02C exit accuracy (error>5% direct elimination)

High voltage fast charging projects mandatory requirement pulse charging patent authorization (e.g. Tesla US10608247B2)

Engineer’s Conclusion:

“On the accelerated aging table at Meta Labs, poor quality charging algorithms can cause a 3000mAh cell to decay to scrap in half a year, while subtle pulse protocols bring decommissioned batteries back to life. Choosing a charging method is choosing a second life for your battery.”